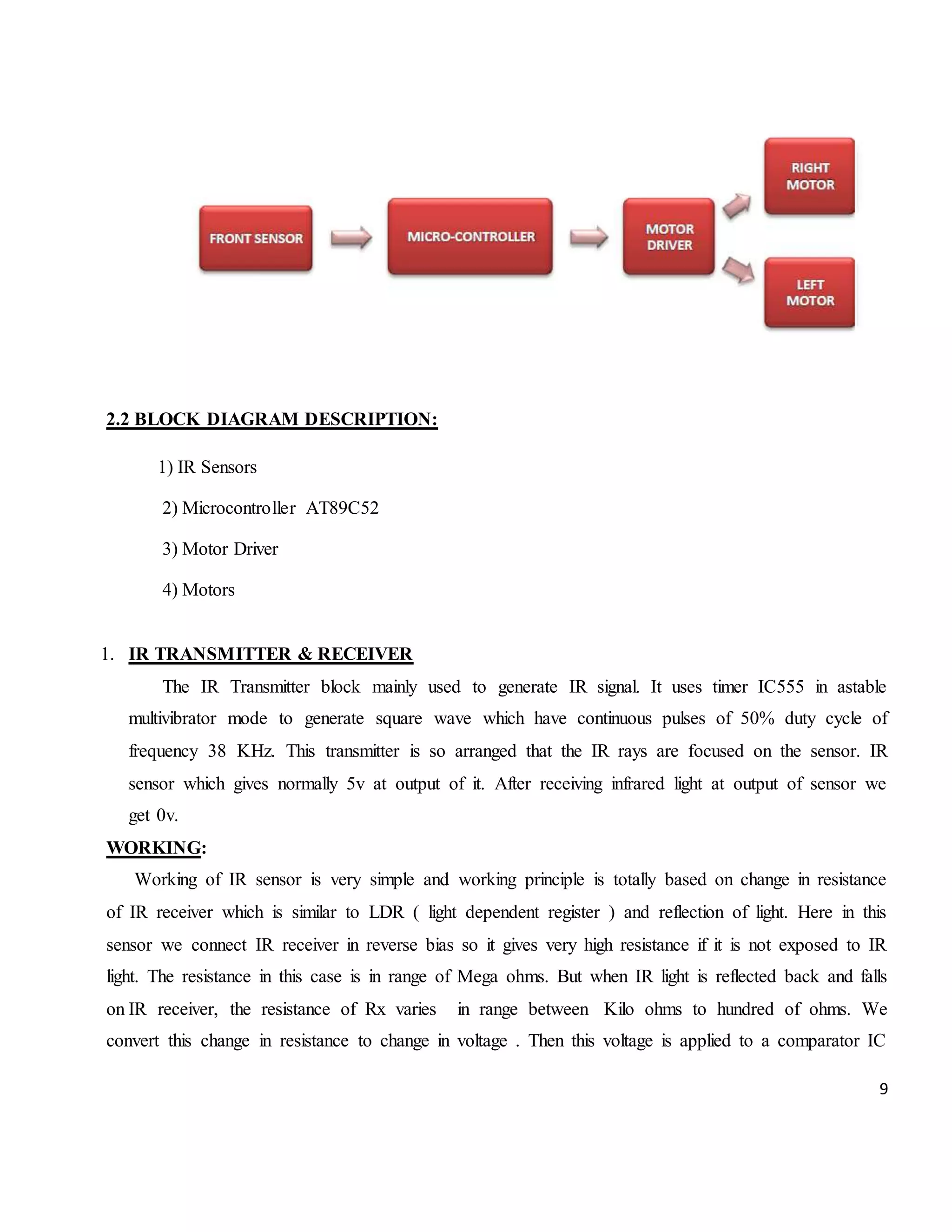

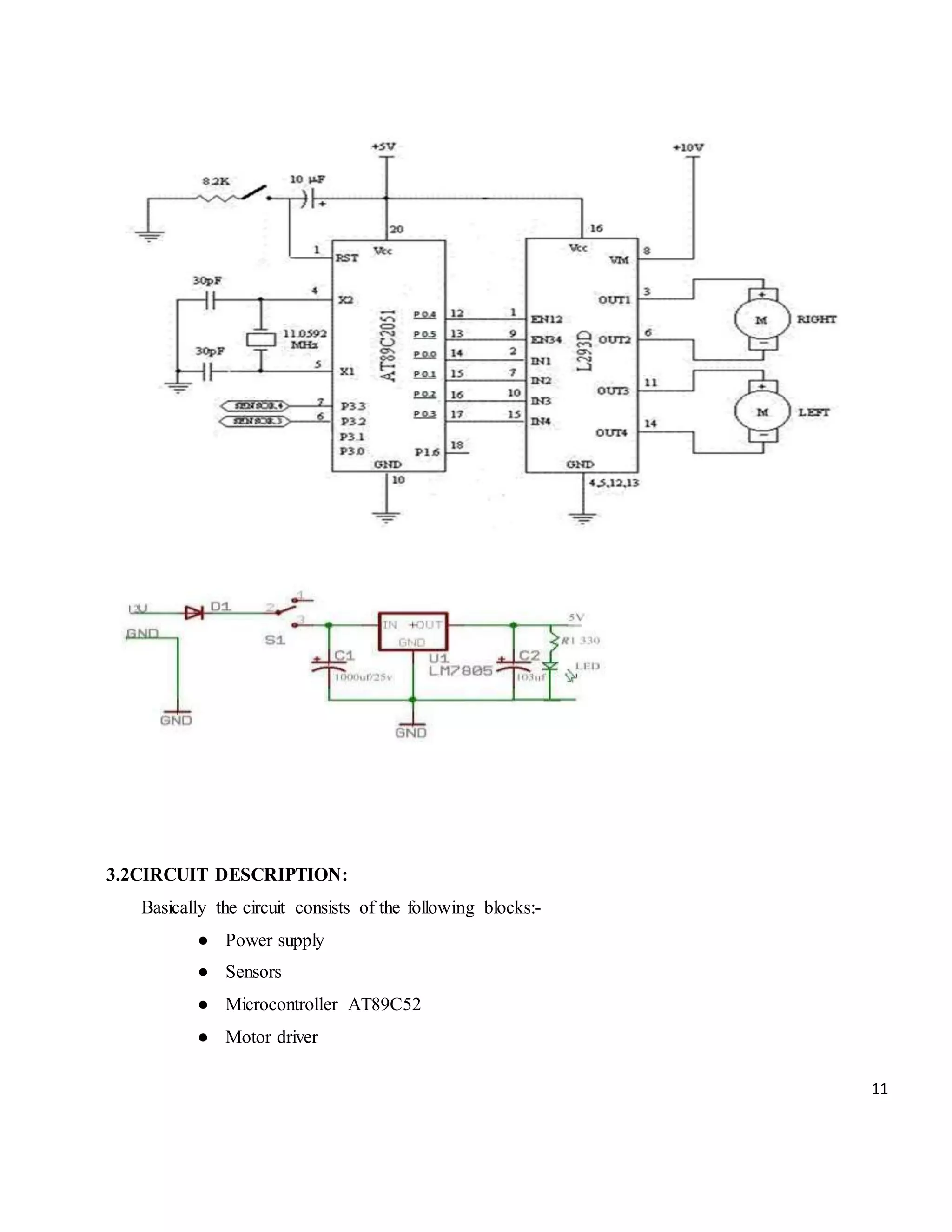

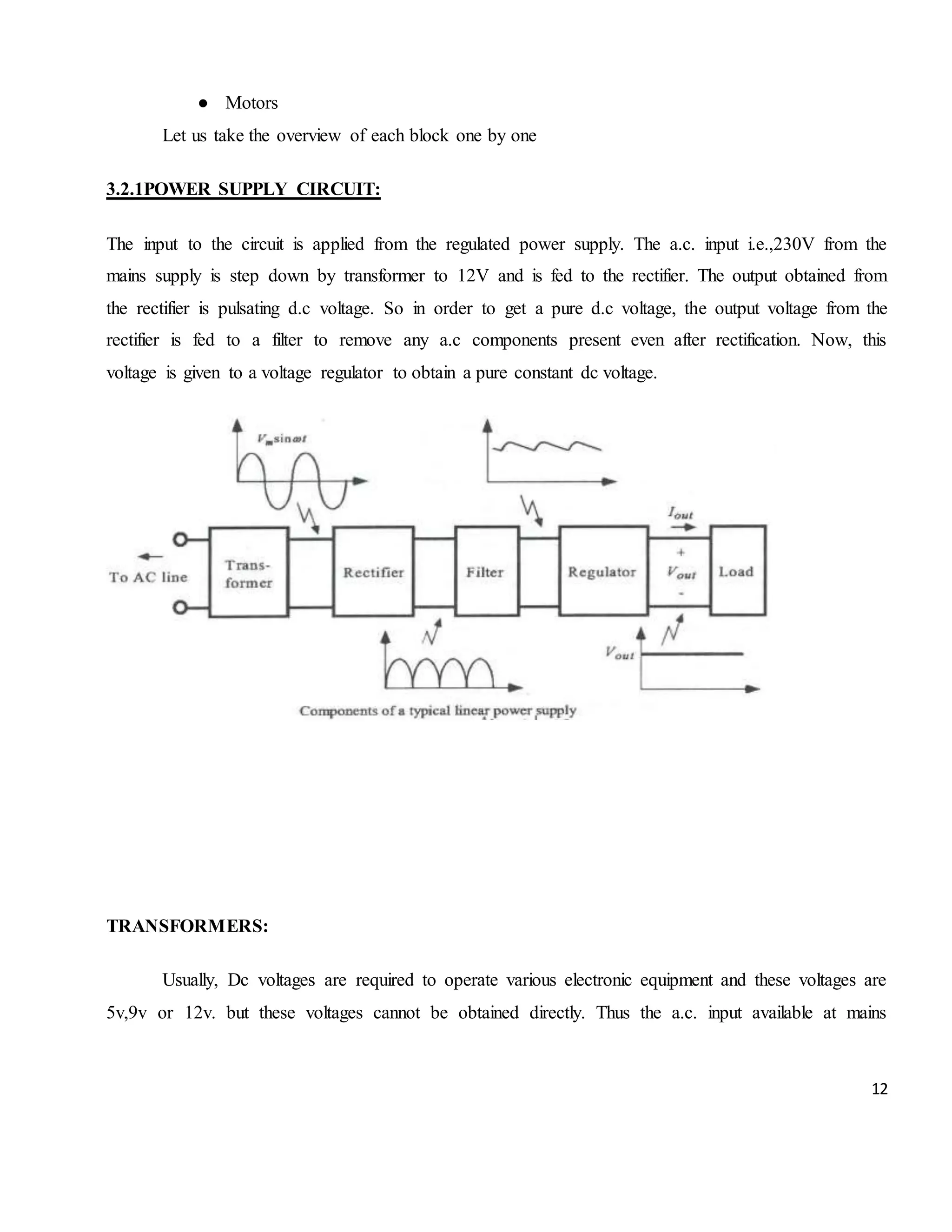

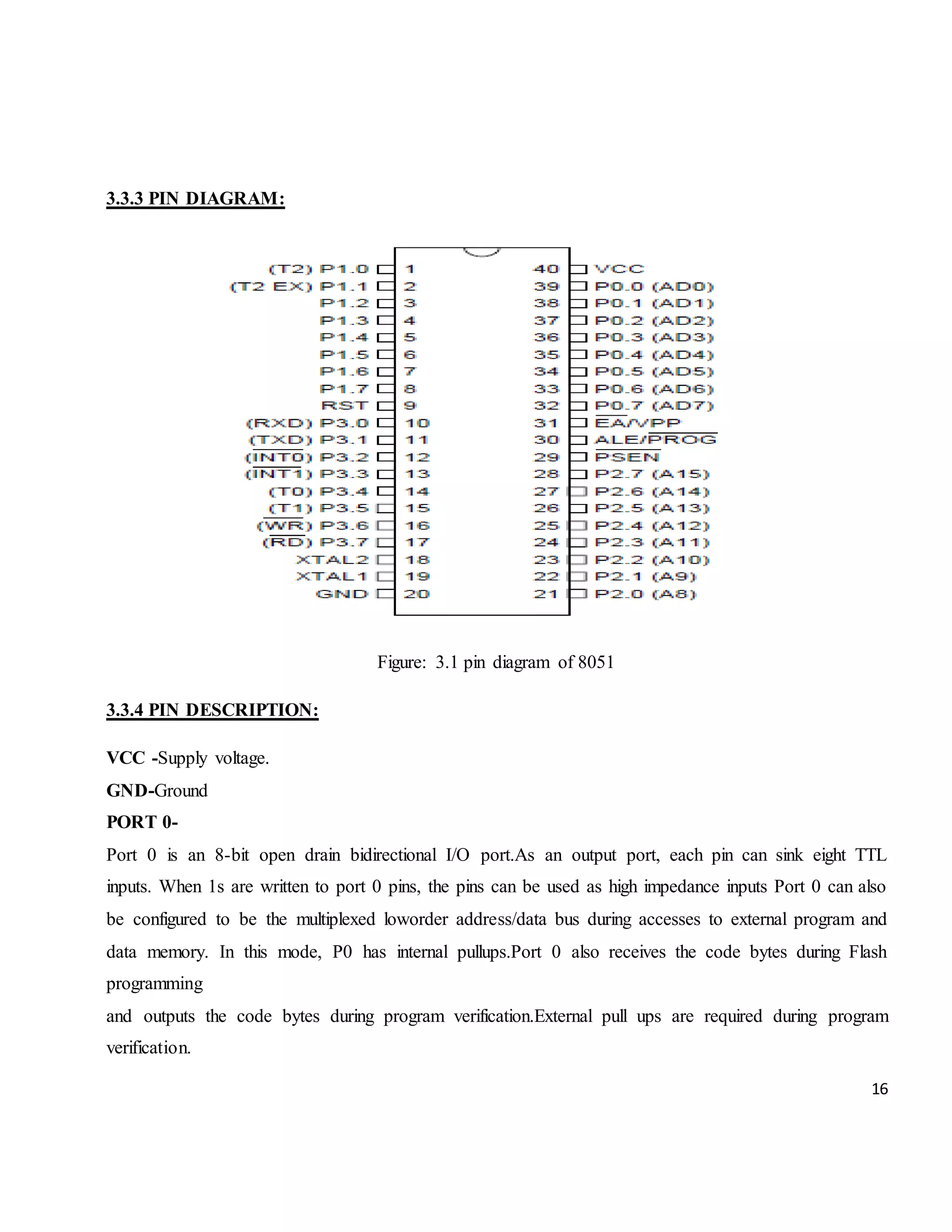

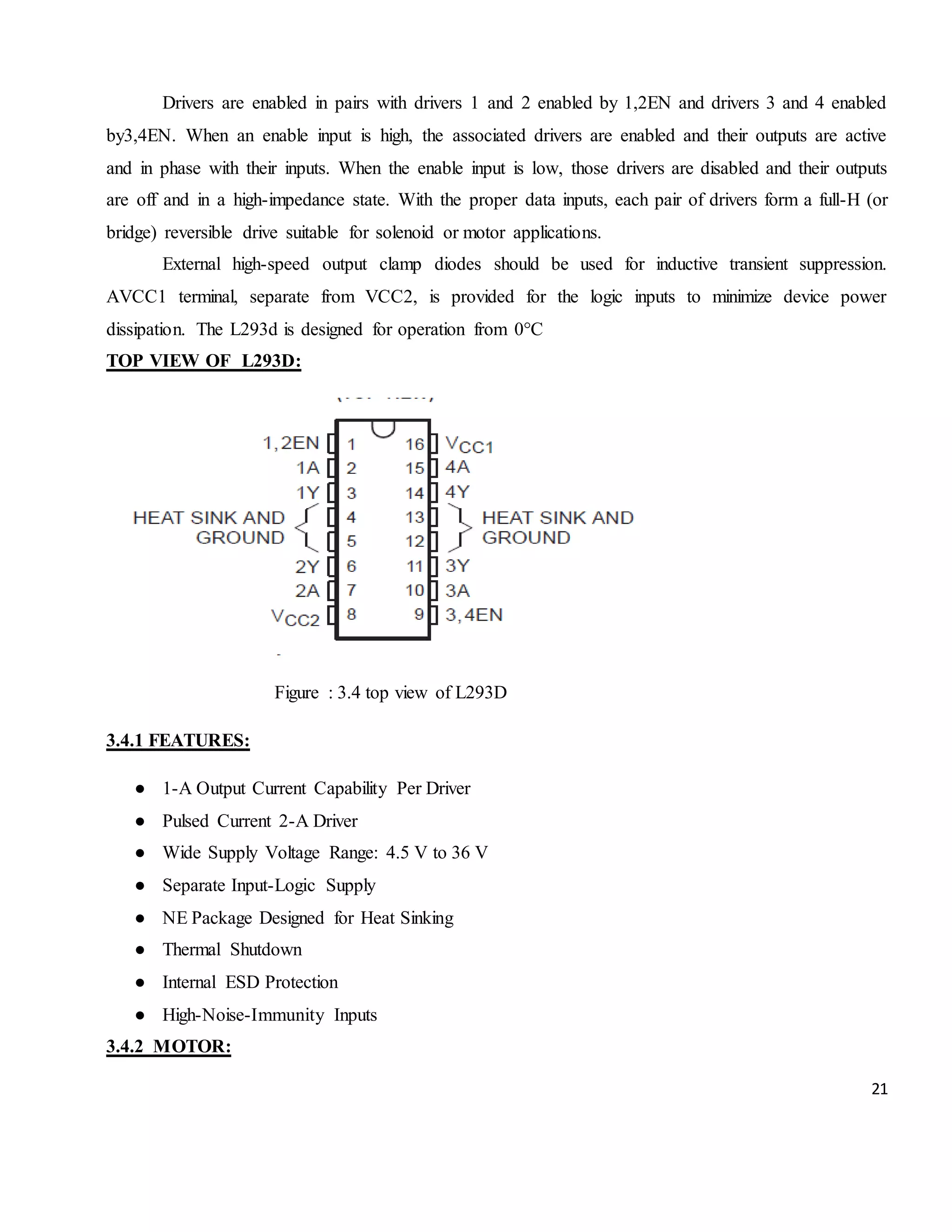

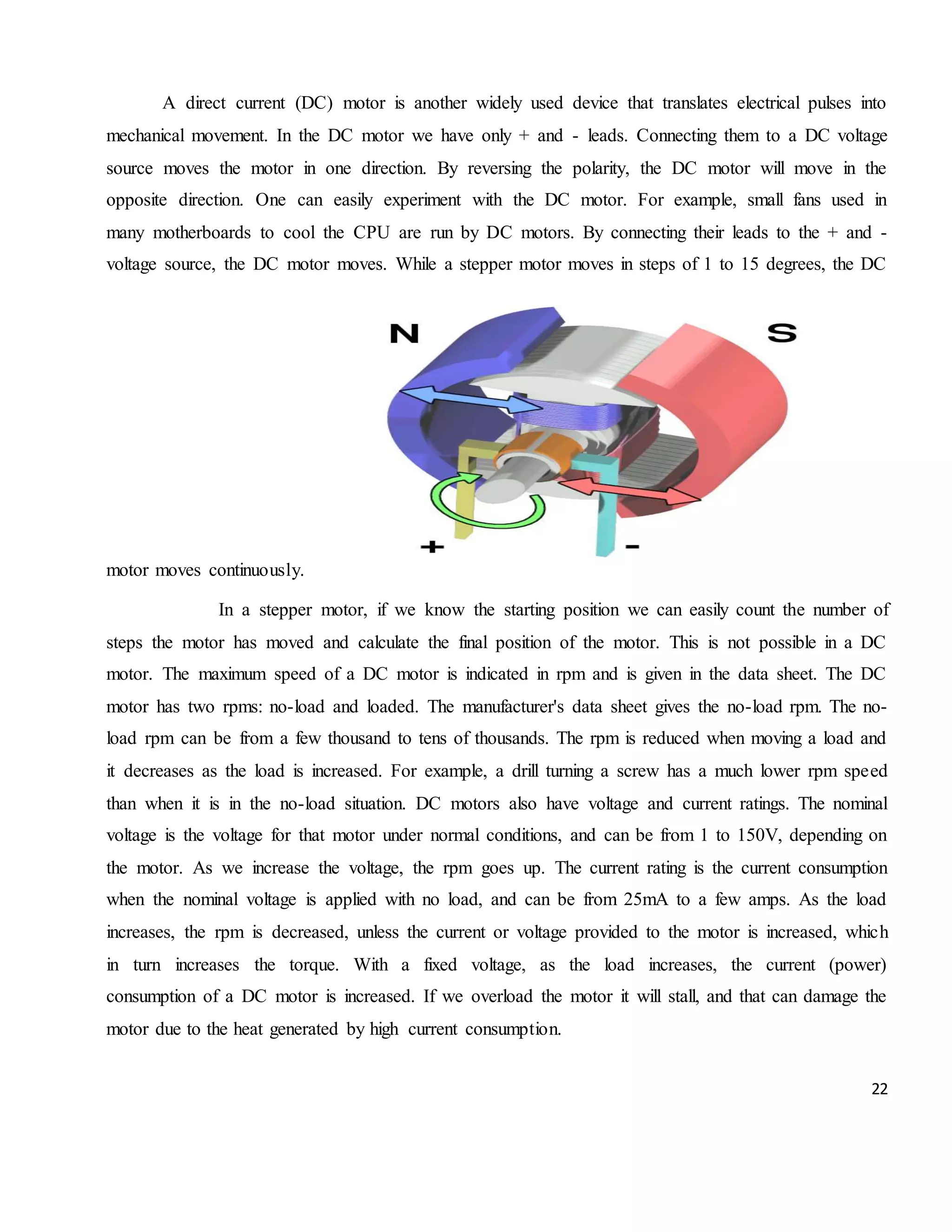

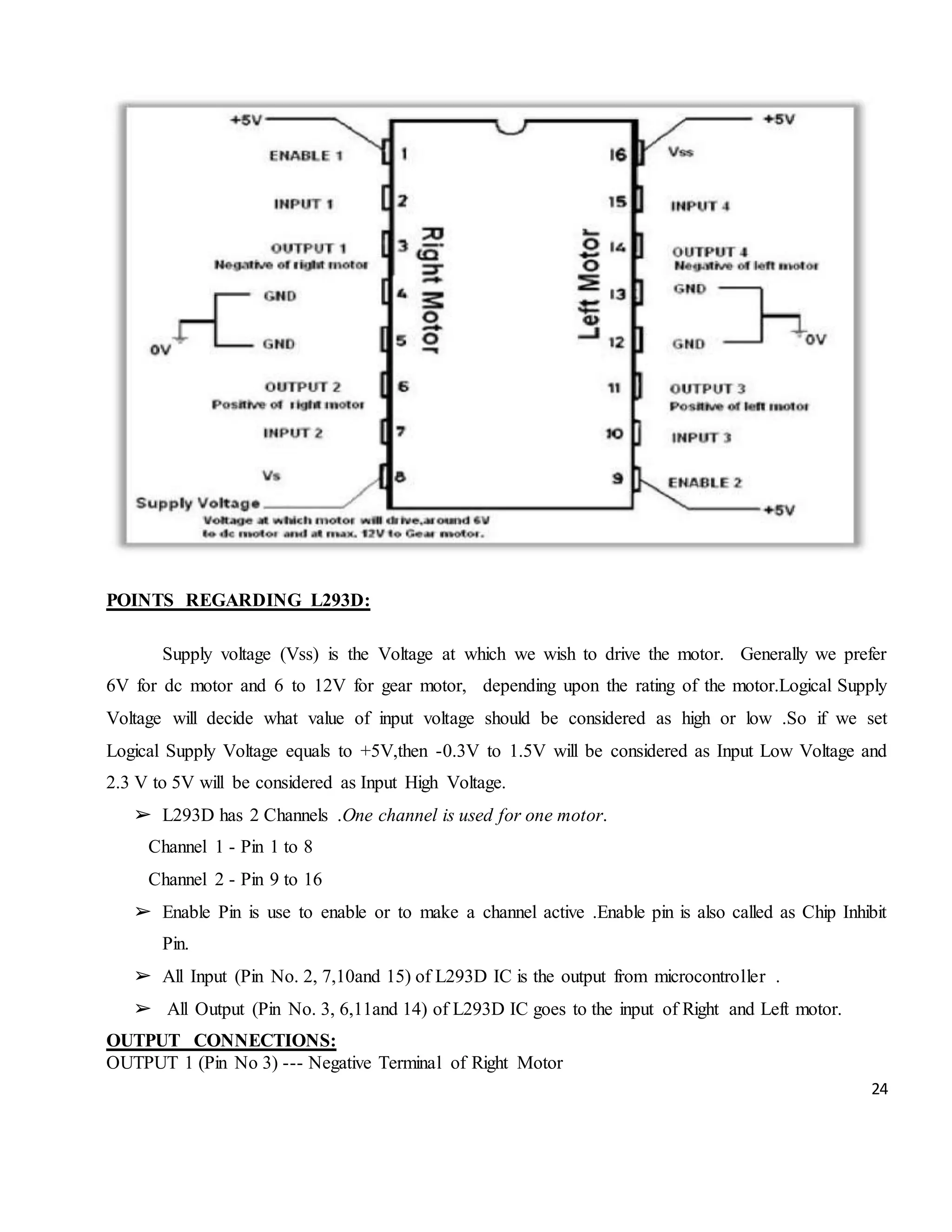

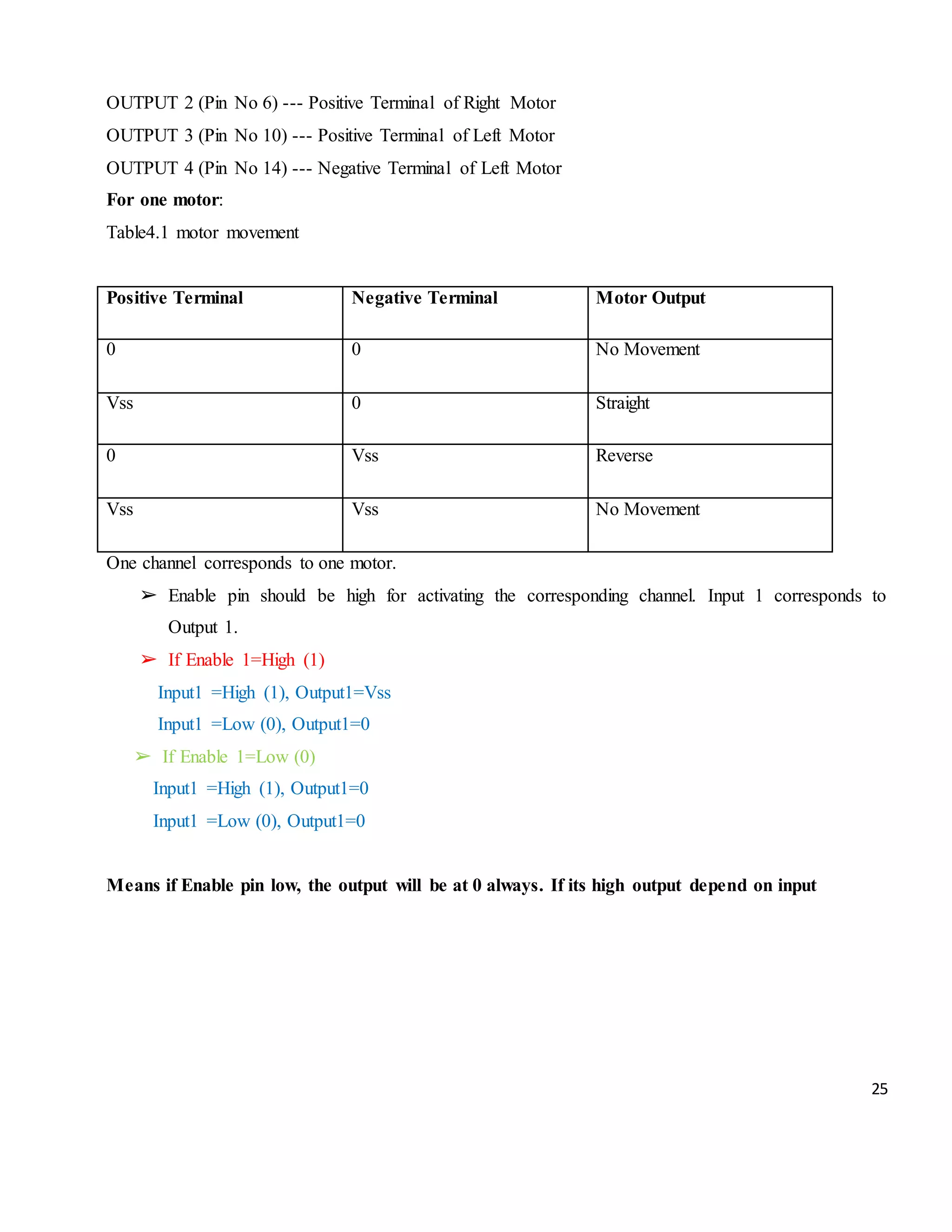

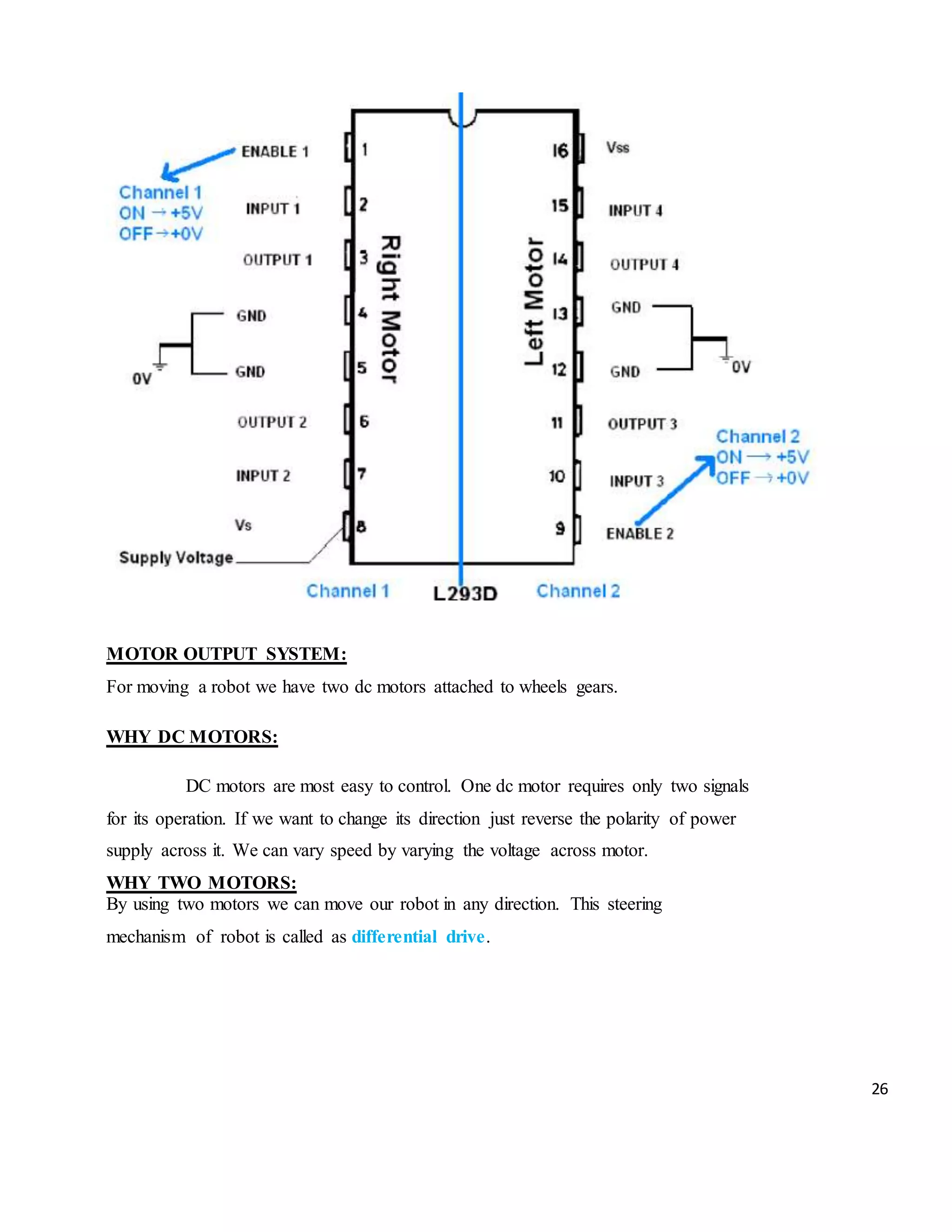

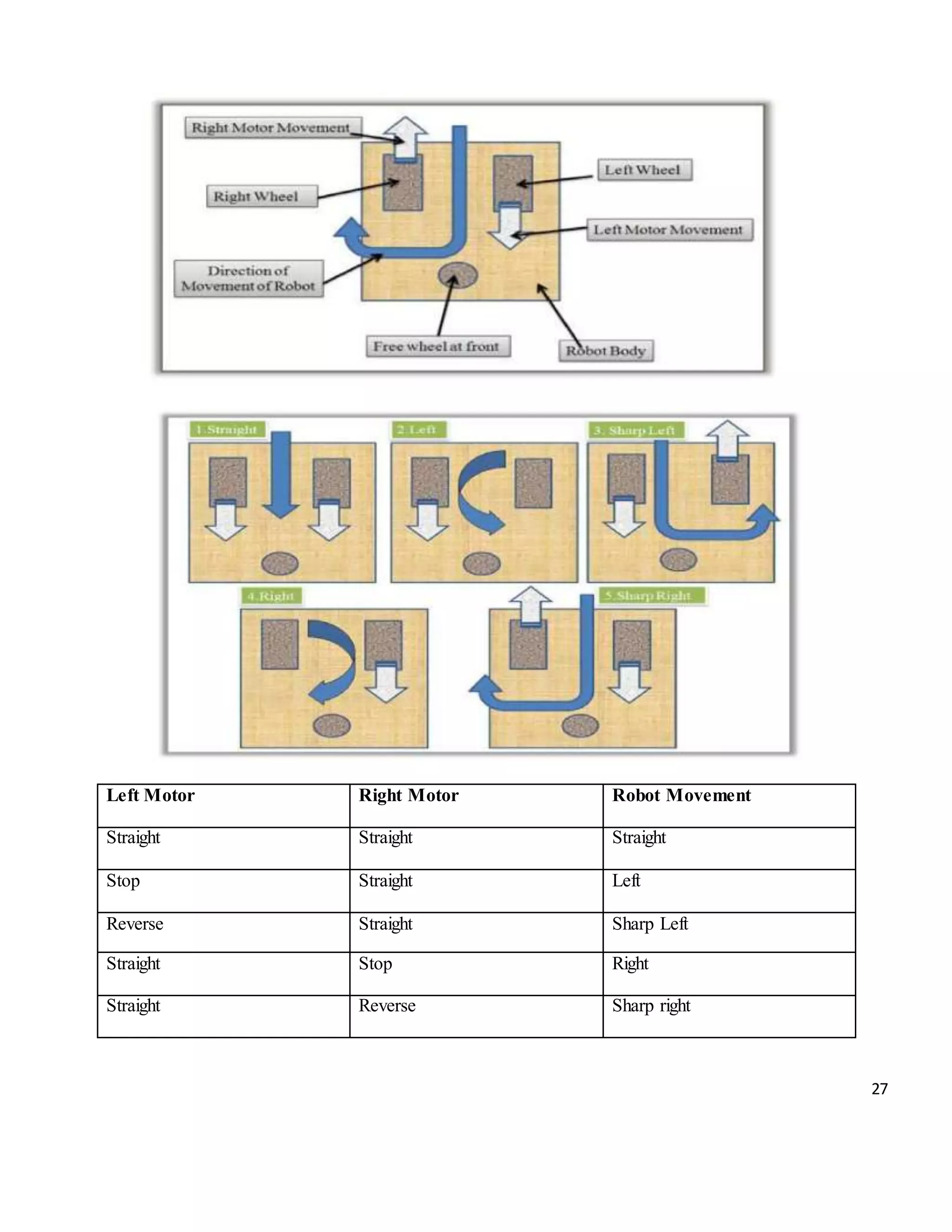

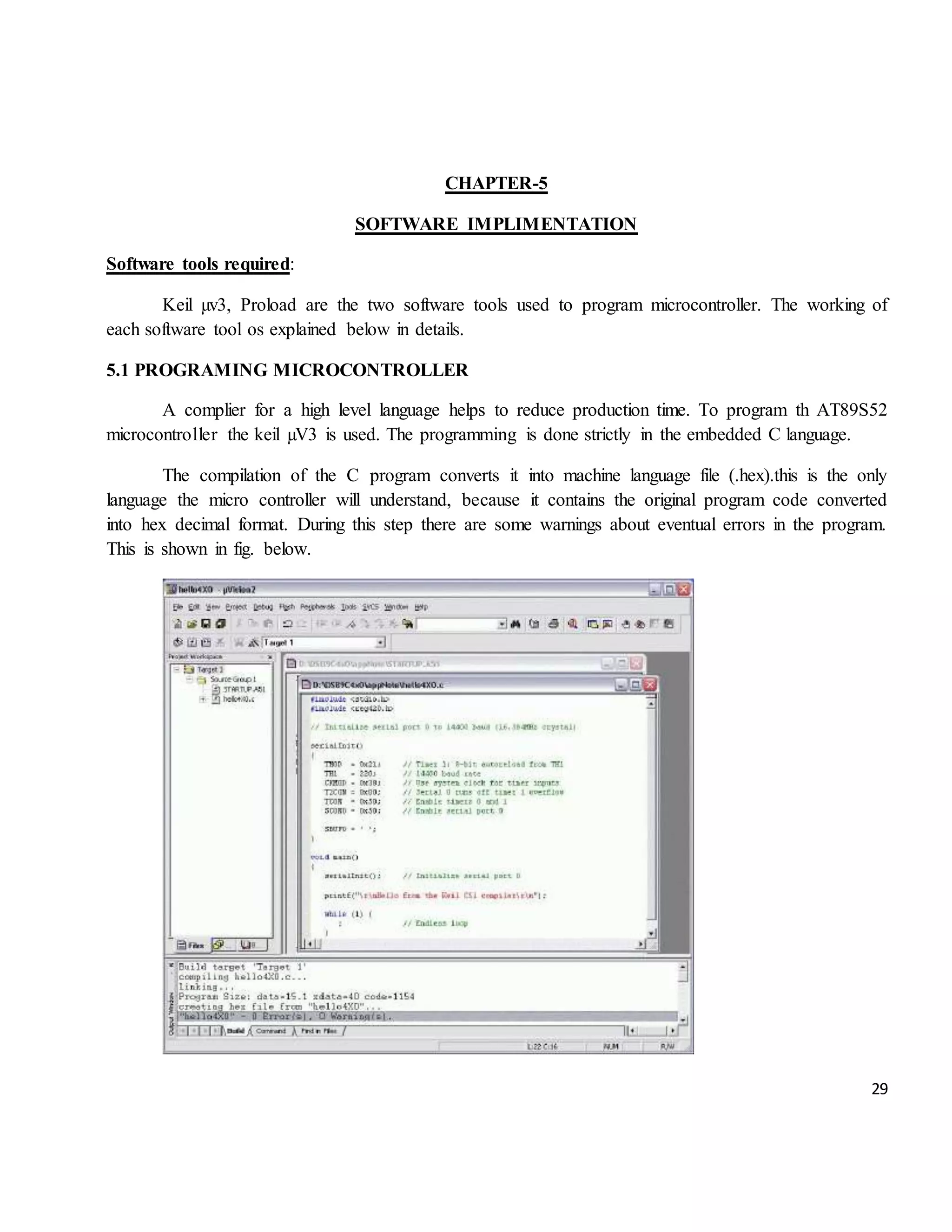

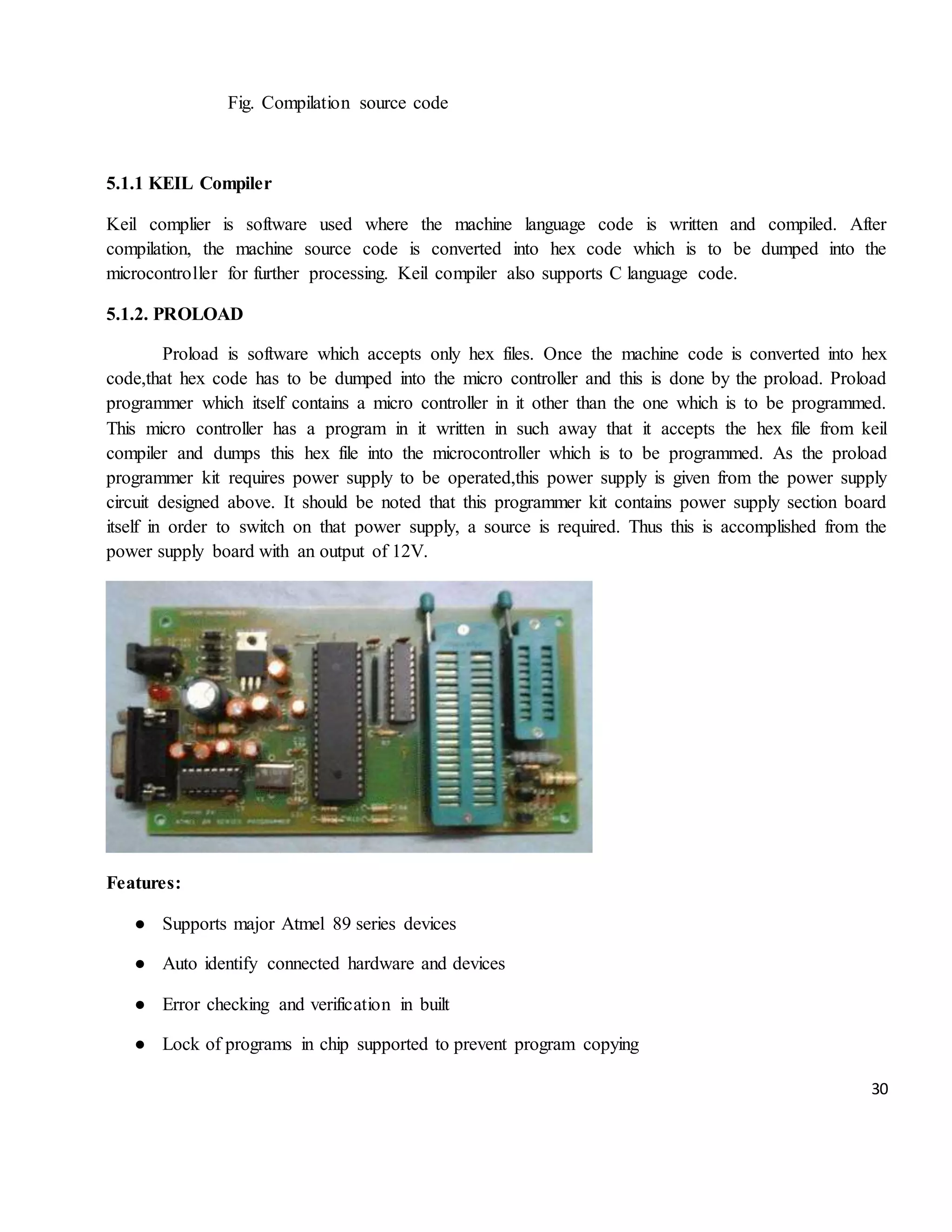

The document is a project report for an 'obstacle avoiding robot' created by K. Sri Arun Sai and Umera Anjum as part of their Bachelor of Technology in Electronics and Communication Engineering at Bharat Institute of Engineering & Technology. It details the design and construction of an automated robot that uses infrared sensors and a microcontroller to detect and avoid obstacles in its path, highlighting its hardware components and programming. Additionally, the report acknowledges the support of faculty and peers, while outlining potential applications for the robot in various fields.