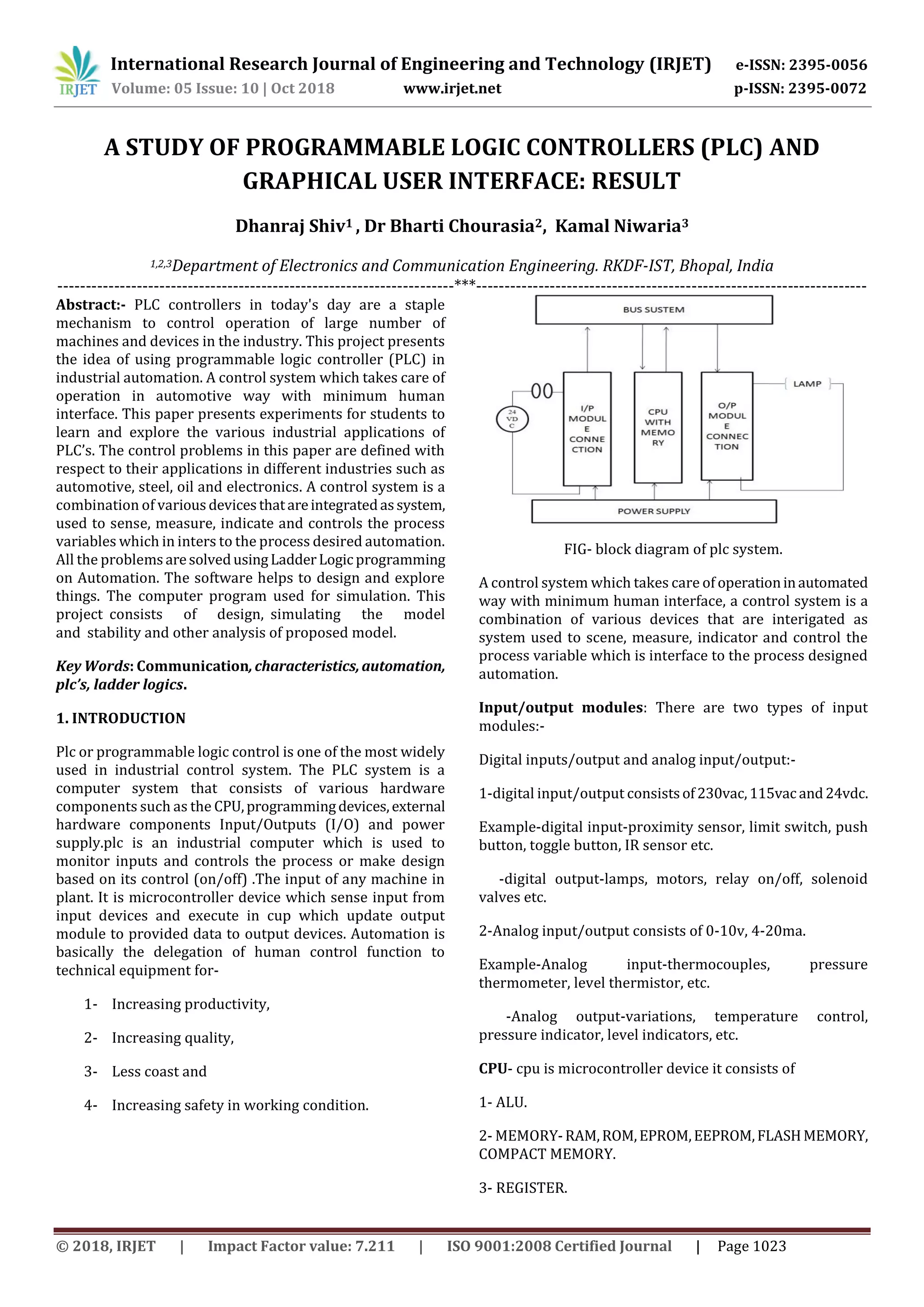

This document discusses programmable logic controllers (PLCs) and their use in industrial automation. It begins with an abstract that outlines how PLCs are widely used to control industrial machines and presents experiments for students to learn about various PLC applications. The next sections describe the basic components of a PLC system, including input/output modules, the central processing unit, and programming software. Ladder logic programming is discussed as a common method to control PLCs. The document concludes that the presented educational approach on PLCs is effective for teaching students about industrial automation and control systems.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 10 | Oct 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 1024 4- TIMER. 5- COUNTER, and 6- PROCESS IMAGE AREA: - I/P image [area/table], O/P [image area/table]. BUS SYSTEM- bus system transmit data or signal between input, output modules, cup and 3process. TYPE OF PLC- 1- COMPACT and 2- MODULAR. In compact plc memory are flexed I/P module, in Modular I/p module depends on project or customer requirement. Compact plc are less memory and modular plc depending on project there used more memory. In compact any fault is observed in any slot {i/p} so required change hardware {plc’s}, in modular case of fault to any slot {i/p} can be easily handle fault by replacing the slots. LADDER LOGIC PROGRAMING USING SOFTWARE (RS LINX, RS LOGIX 500, SIMATIC MANAGER) One of the widely used methods of controlling PLCs is using Ladder logic programming. The ladder logic diagram is a representation of the steps of programming. INPUT address can be used in series and parallel. OUTPUT address can be used in parallel. OUTPUT address can be used as INPUT address. INPUT address not be used as OUTPUT address. INPUT address can be repeated as INPUT address. OUTPUT latch and unlatch OUTPUT coil. The ladder program is all PLCs follow a template that consists of 2 bus bars that are connected to one another using rung lines. FIG -RS LINX LITE NOTE- RS LINX LITE is for configuration with RSLOGIX500.in RSLOGIX 500 we chosen input/output configuration, microcontroller etc. in this we design programs and run it through RSLOGIX 500. Same in SIMATIC MANAGER SIMATIC MANAGER are using for SIMESNS PLC. FIG- RS LOGIX 500 FIG- SIMATIC MANAGER CONCLUSION A software tool and hardware for teaching/learning the microcontroller based PLC, called EasyLadder, andhasbeen presented. It can be used when describing the PLC architecture, the Ladder logic instruction set or the embedded peripherals operation, and also to write and test Application programs. The main advantages of thisplatform are its versatility, design flexibilityandlowcostcompared to commercially available products as a teaching point of view. It is considered that this platform has an impact in the automation where PLC is the part of system and so student can understand heart of the system. The source codes of EasyLadder are open to studentsothateveryonemakestheir own small PLC using editing the codes. Also, the authors consider that this system is a platform on which a more powerful PLC can be developed in future. The results of the application of our approachtoeducationhavebeenexcellent both in terms of student’s motivation and knowledge.](https://image.slidesharecdn.com/irjet-v5i10190-181102112502/75/IRJET-A-Study-of-Programmable-Logic-Controllers-PLC-and-Graphical-User-Interface-Result-2-2048.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 05 Issue: 10 | Oct 2018 www.irjet.net p-ISSN: 2395-0072 © 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 1025 RESULT This project we have learn how to design a program and familiar to plc drives. Students are learn here how to create program. The plc drives are typically chosen for interface with program. Plc Drives are helping to run program and monitoring. This project helps student to create program and run through plc drive. Software is used to create program and helps to understand it. Students can use this project to understand plc programming and drive understanding. This project helps to learners to understand plc programming. ACKNOWLEDGMENT I am grateful to staff member of electronics and communication department of RKD Institute of Science And Technology, Bhopal (M.P.) for the opportunitytopursuethis Master’s project in a specialized area of interest and wish to express my sincere appreciation and gratitude to himforhis guidance throughout the course of this project. My sincere thank also to all other faculty members of the department for their valuable suggestions and comments. REFERENCE [1] Michael Vine, “Visual Basic Programming (For the absolute beginner)”. [2] Vincet Himpe, “Visual Basic for electronics engineering applications”. [3] David I. Schneider, “Computer Programming Concepts and Visual Basic”. [4] Clayton Walnum, “Complete Idiot's Guide to Visual Basic 6” ISBN: 078971812x, Publication Date: 12/15/98. [5] L.A. BRYAN and E.A. BRYAN.” ProgrammableControllers. [6] Theory and implementation, by L.A. BRYAN and E.A. BRYAN. [7] Prolific Institute for Automation. [8] Schuler Industrial Automation modules.](https://image.slidesharecdn.com/irjet-v5i10190-181102112502/75/IRJET-A-Study-of-Programmable-Logic-Controllers-PLC-and-Graphical-User-Interface-Result-3-2048.jpg)