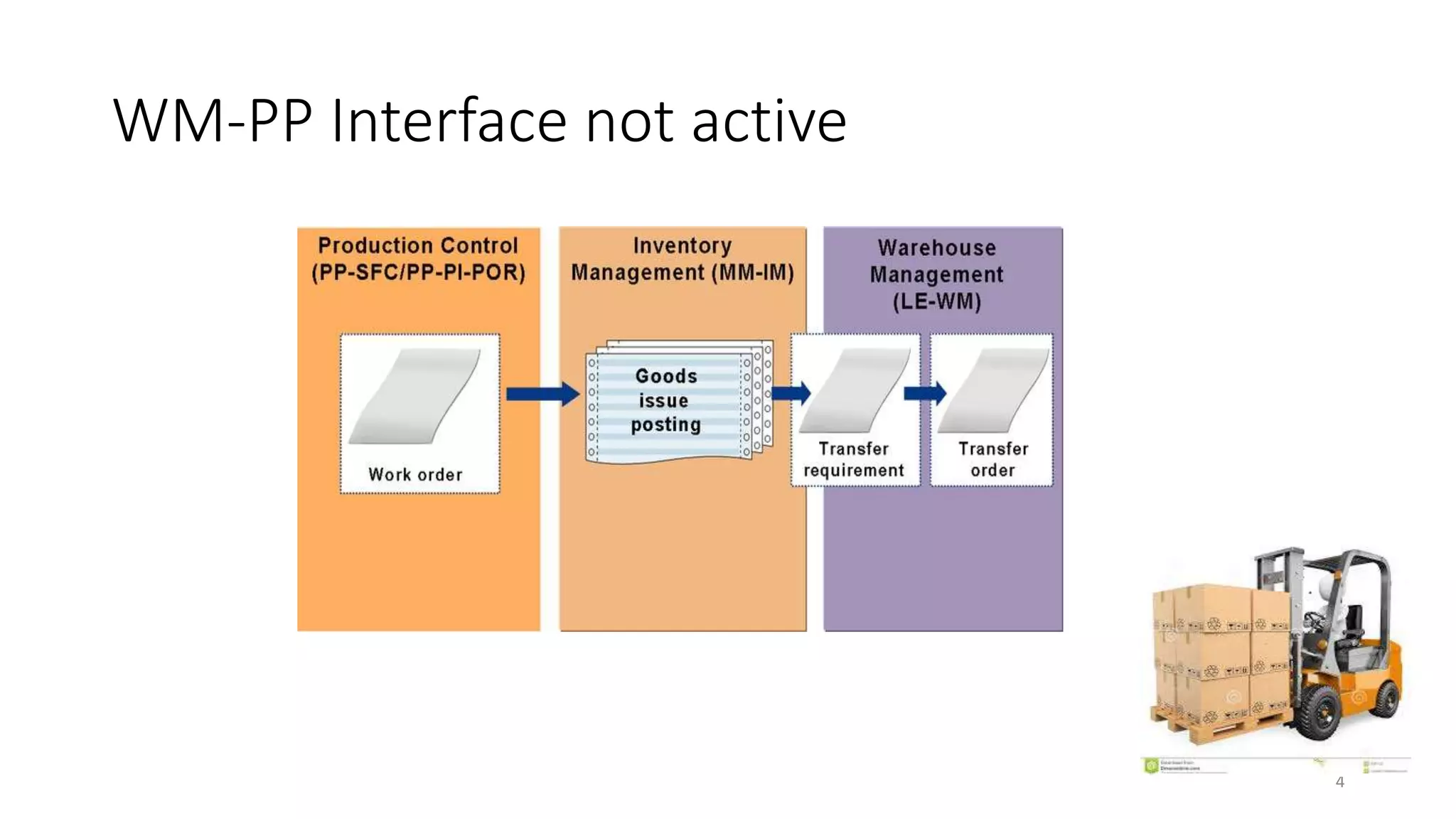

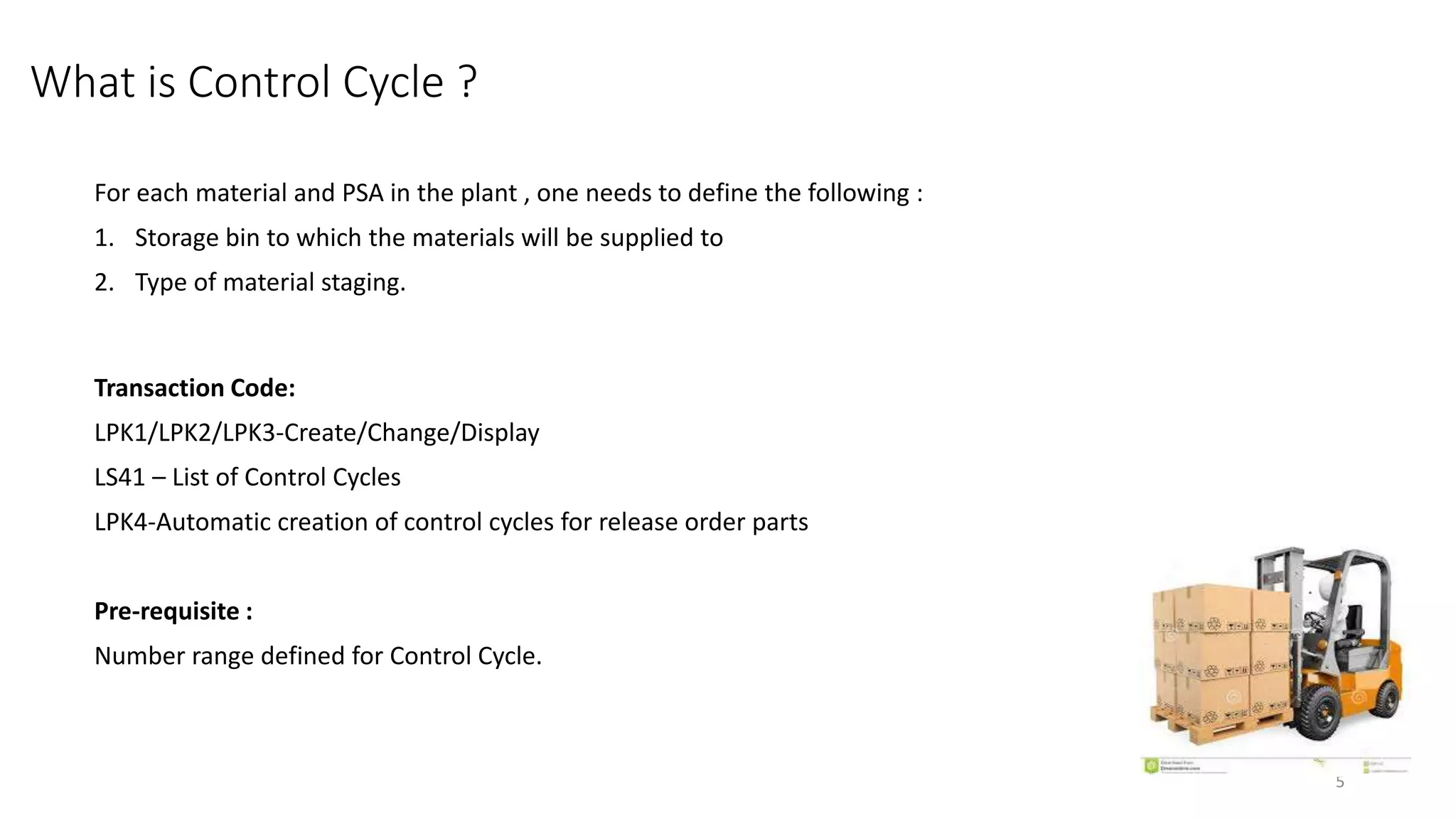

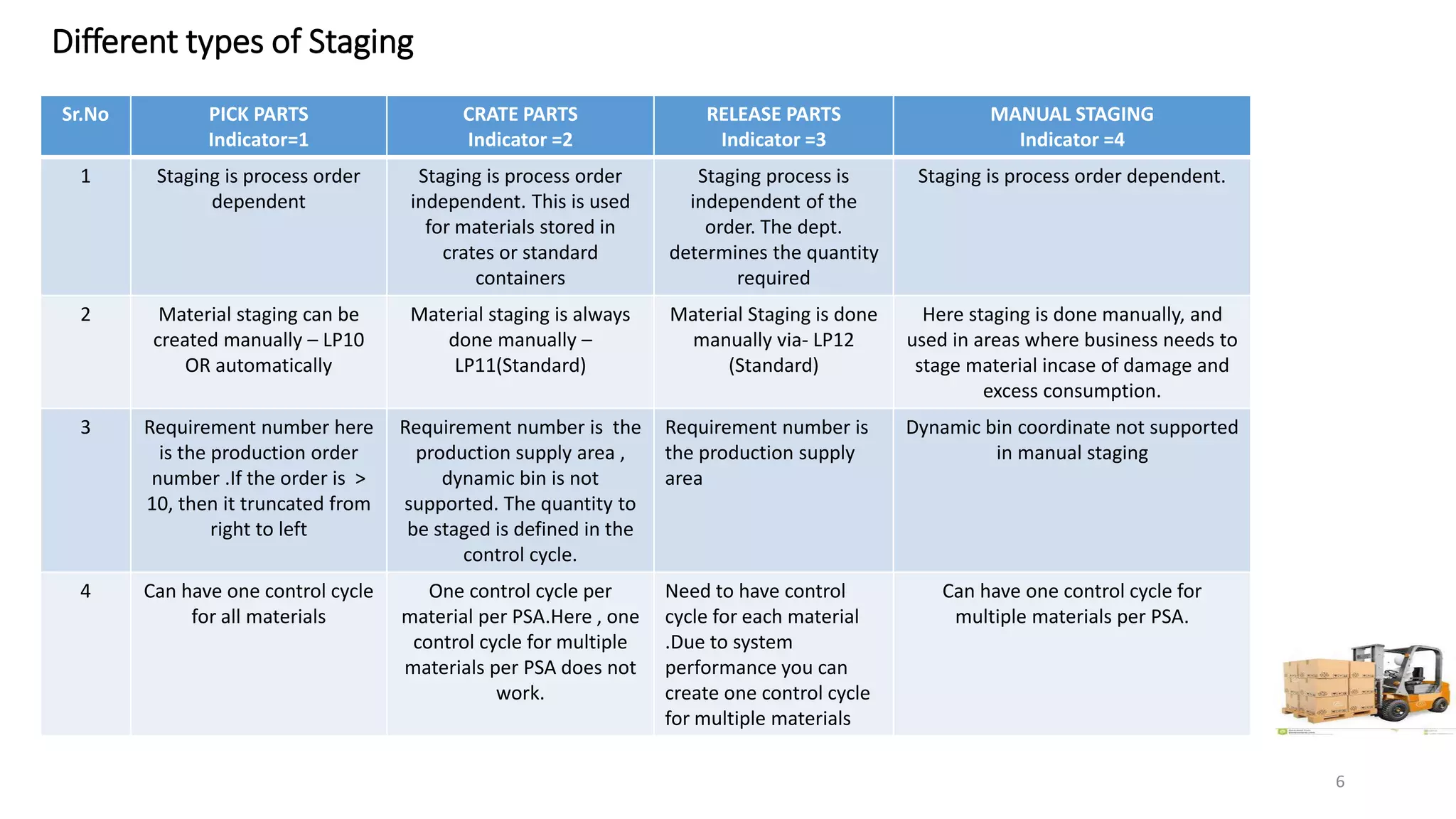

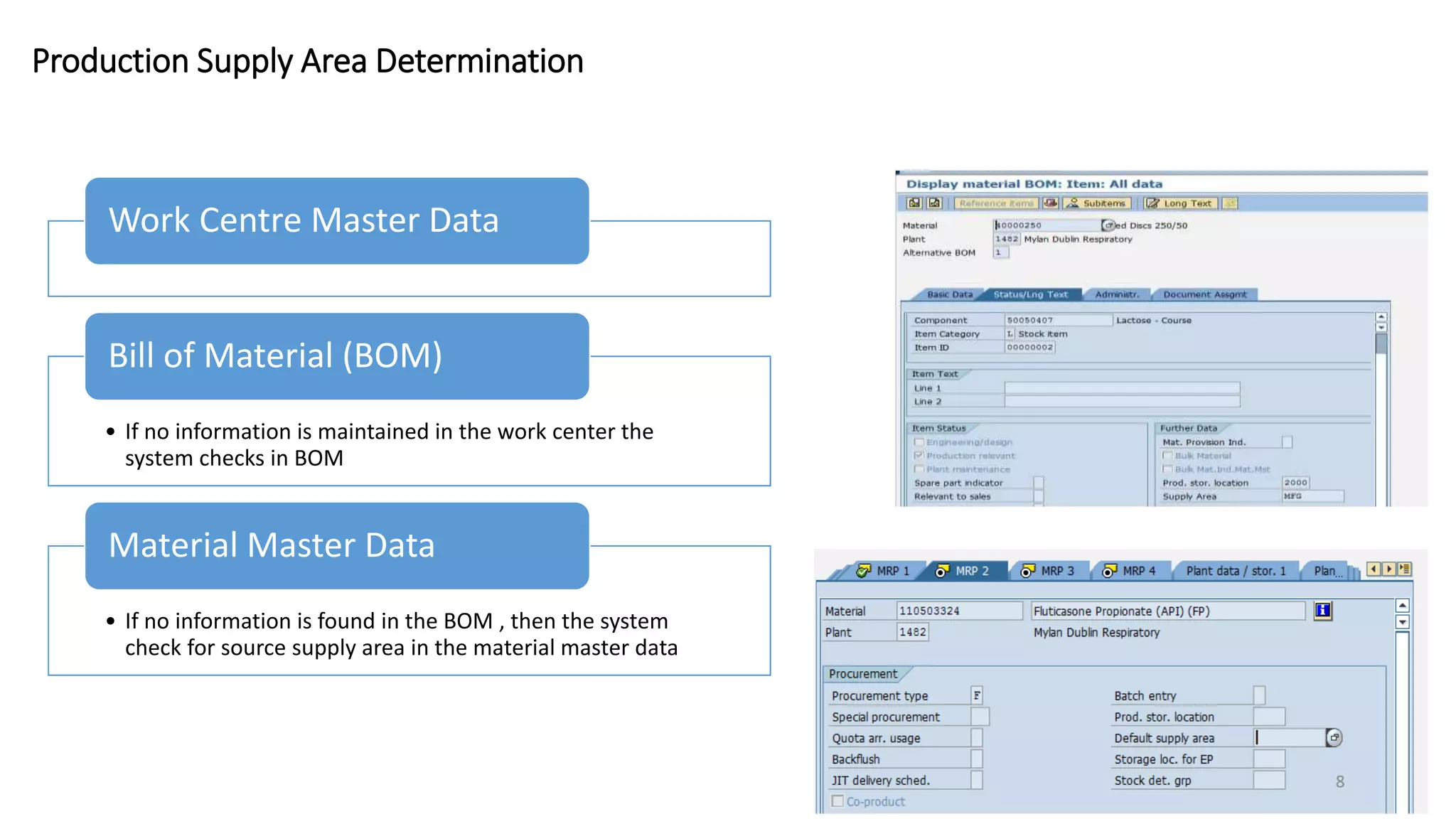

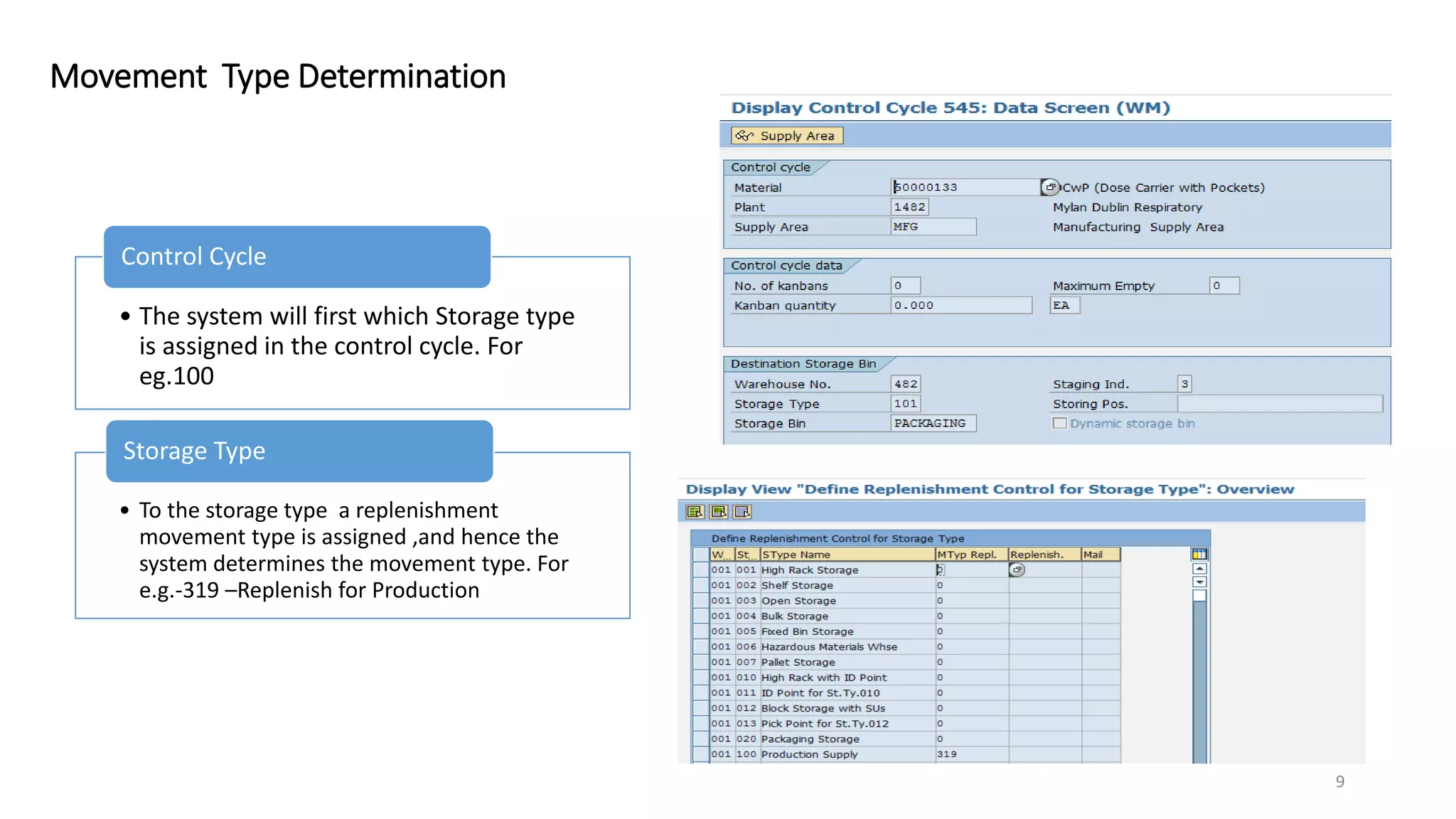

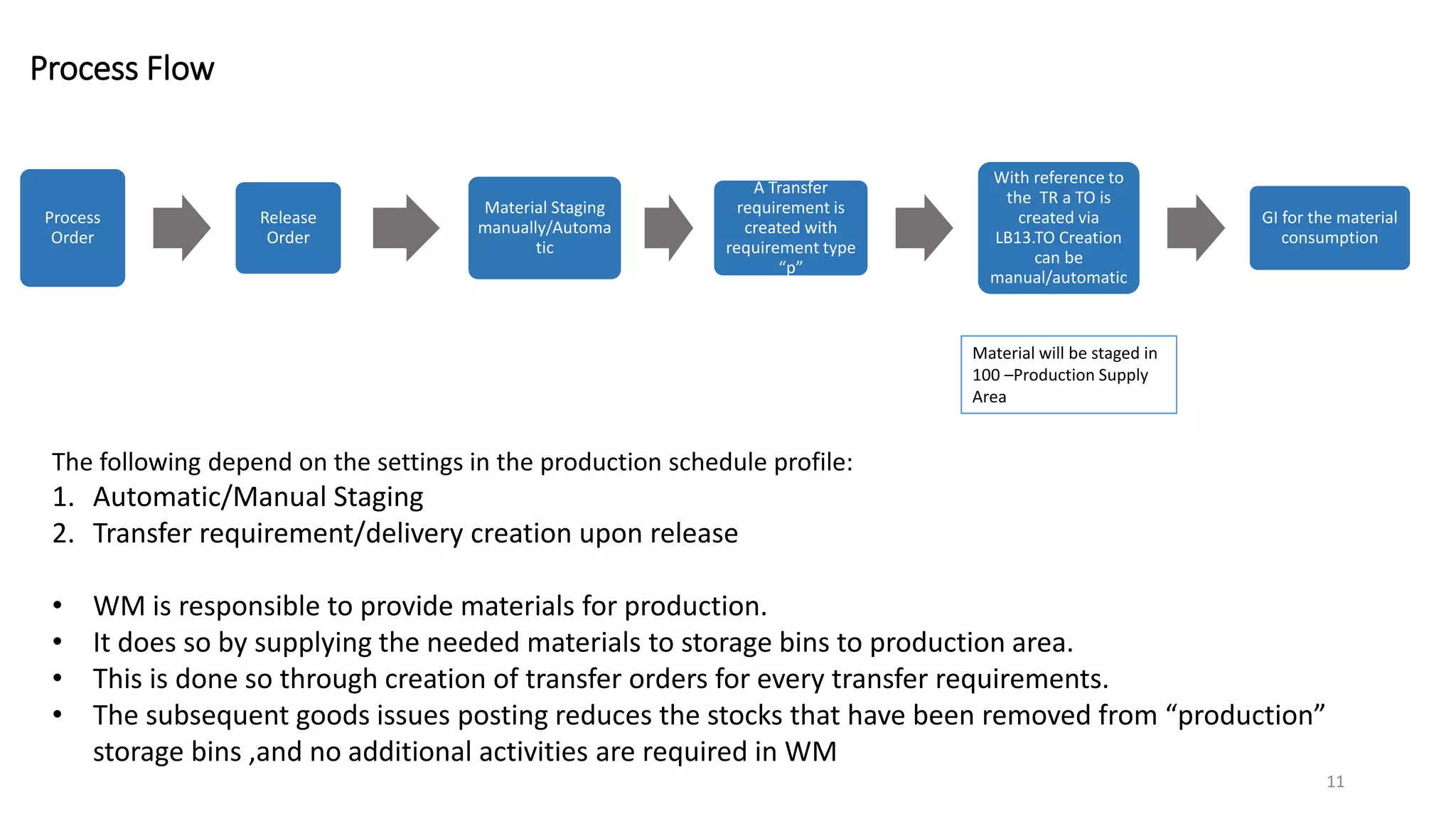

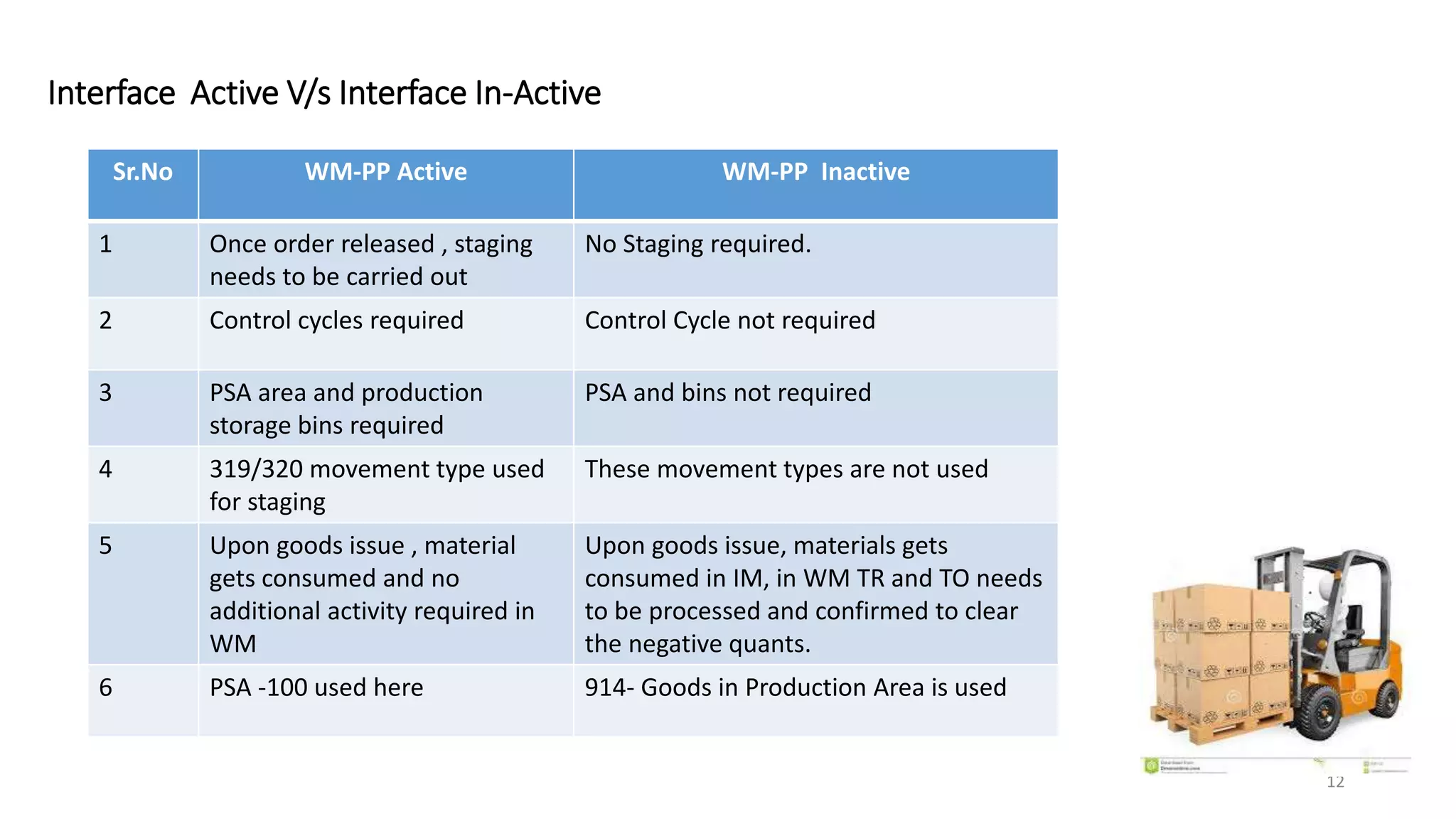

The document outlines the integration of warehouse management (WM) with inventory, quality management, production planning, and shipping, focusing on the WM-PP interface. It explains the scenarios for active and inactive interfaces, control cycle definitions, material staging methods, and the production supply area (PSA) setup for efficient material handling in production processes. It highlights differences in operations between active and inactive interfaces, emphasizing the importance of staging, control cycles, and movement types in material management.