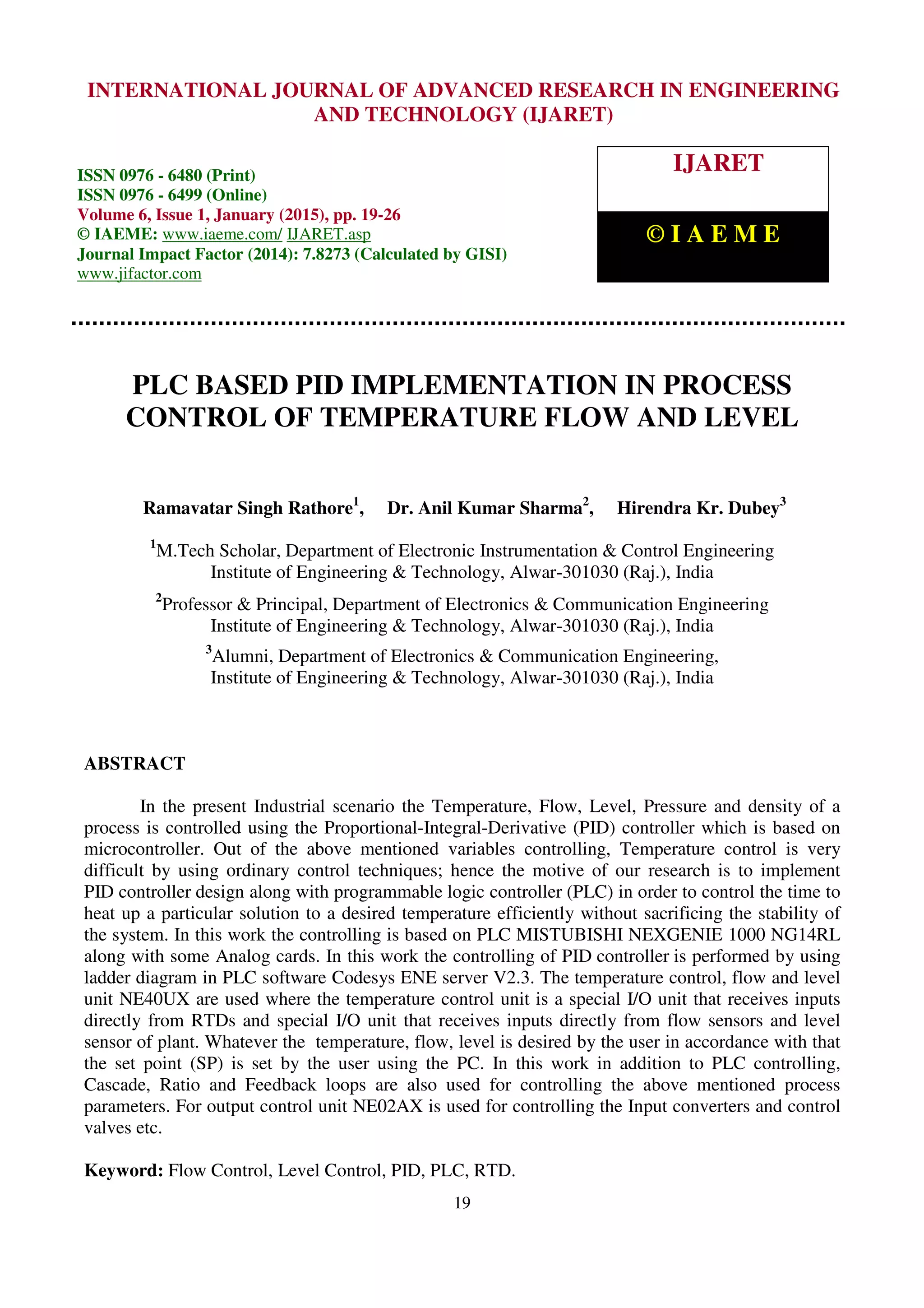

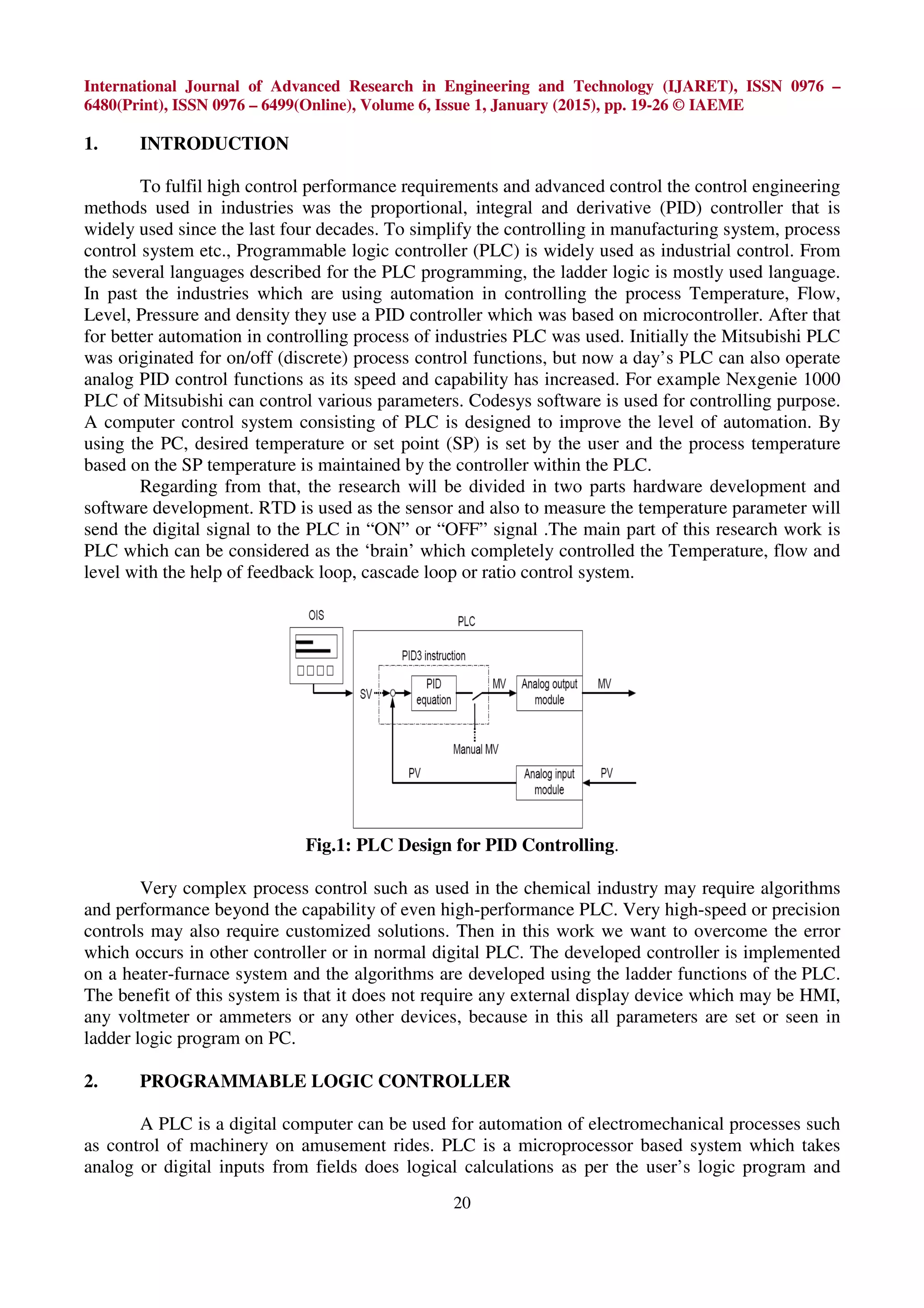

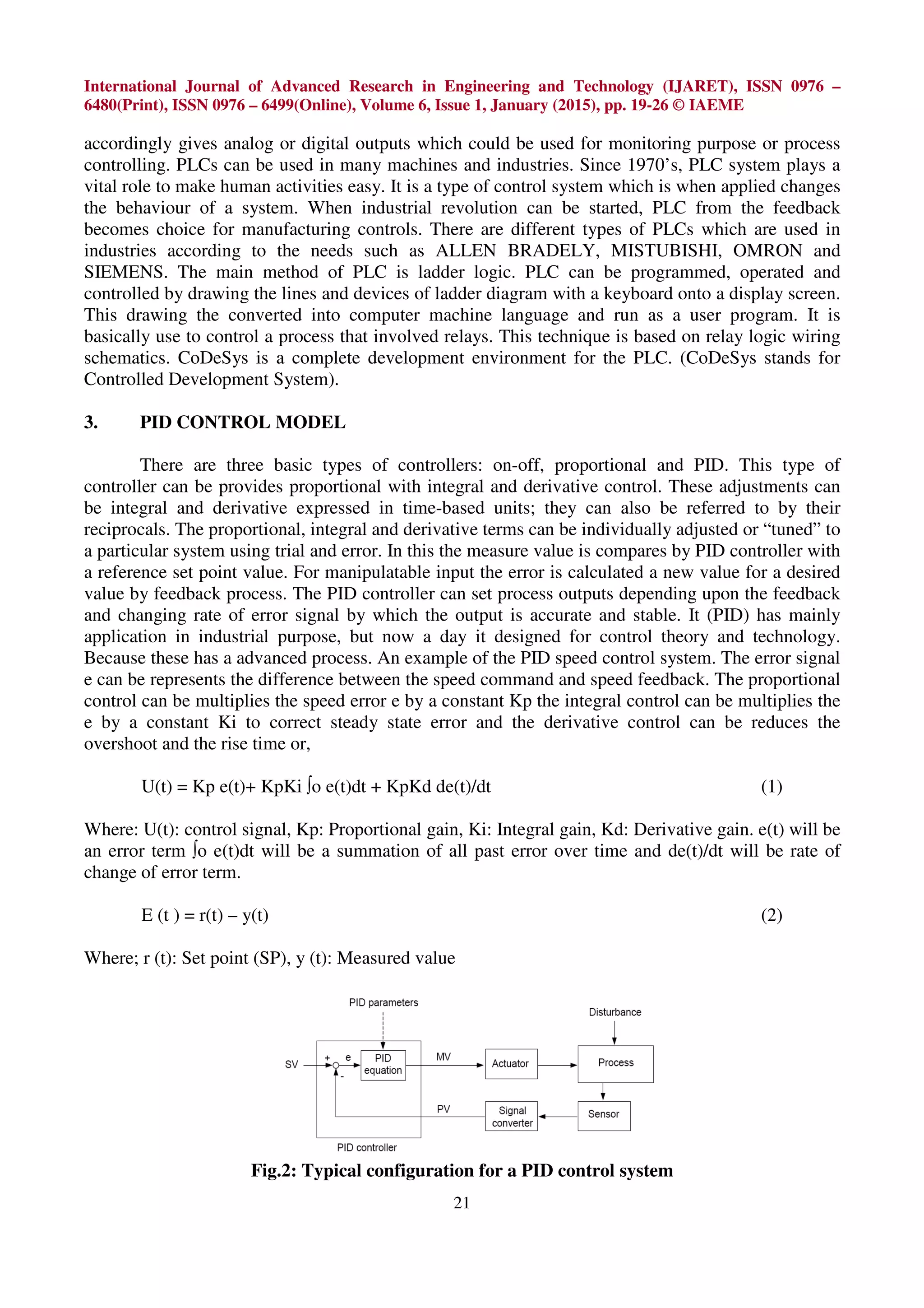

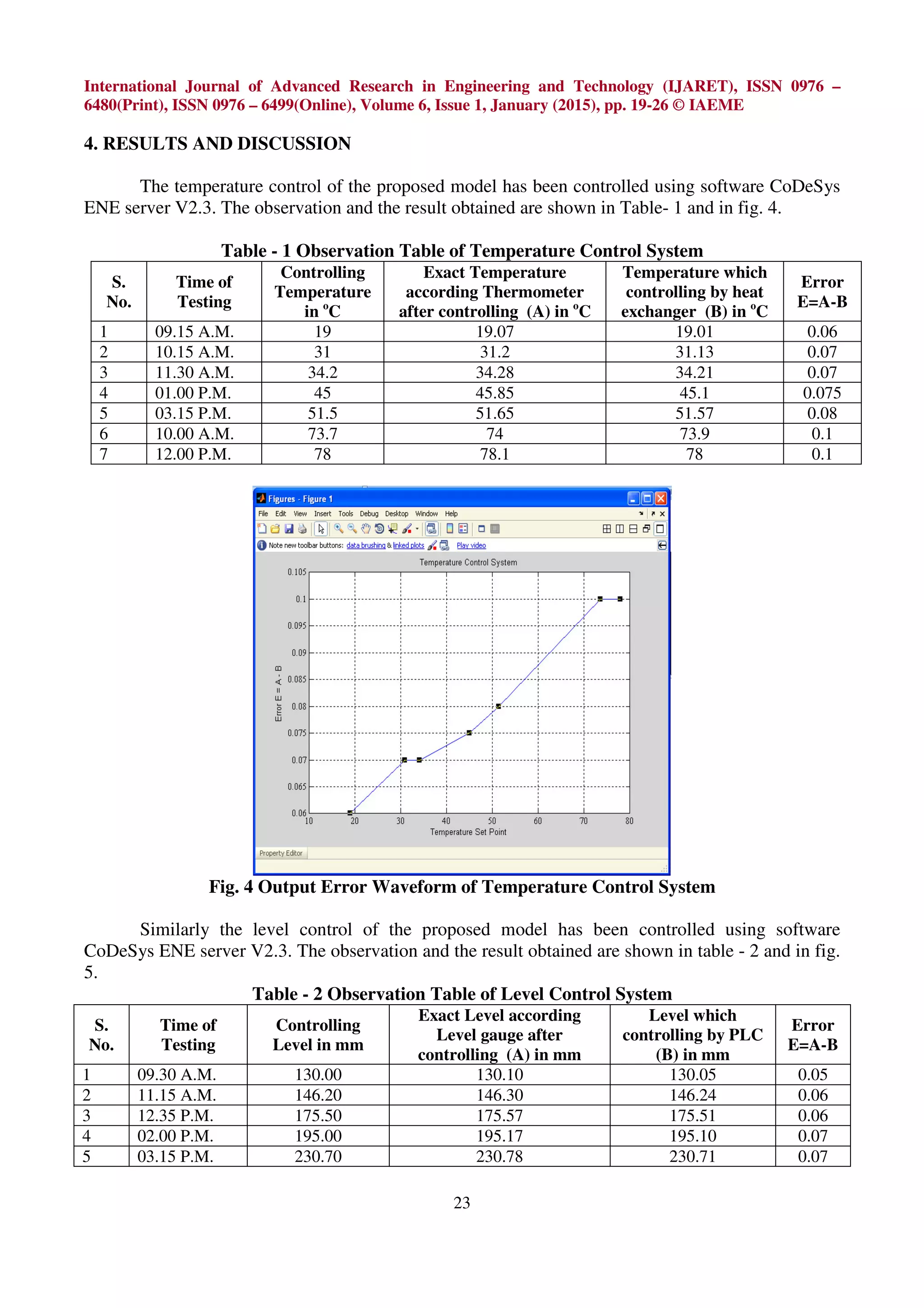

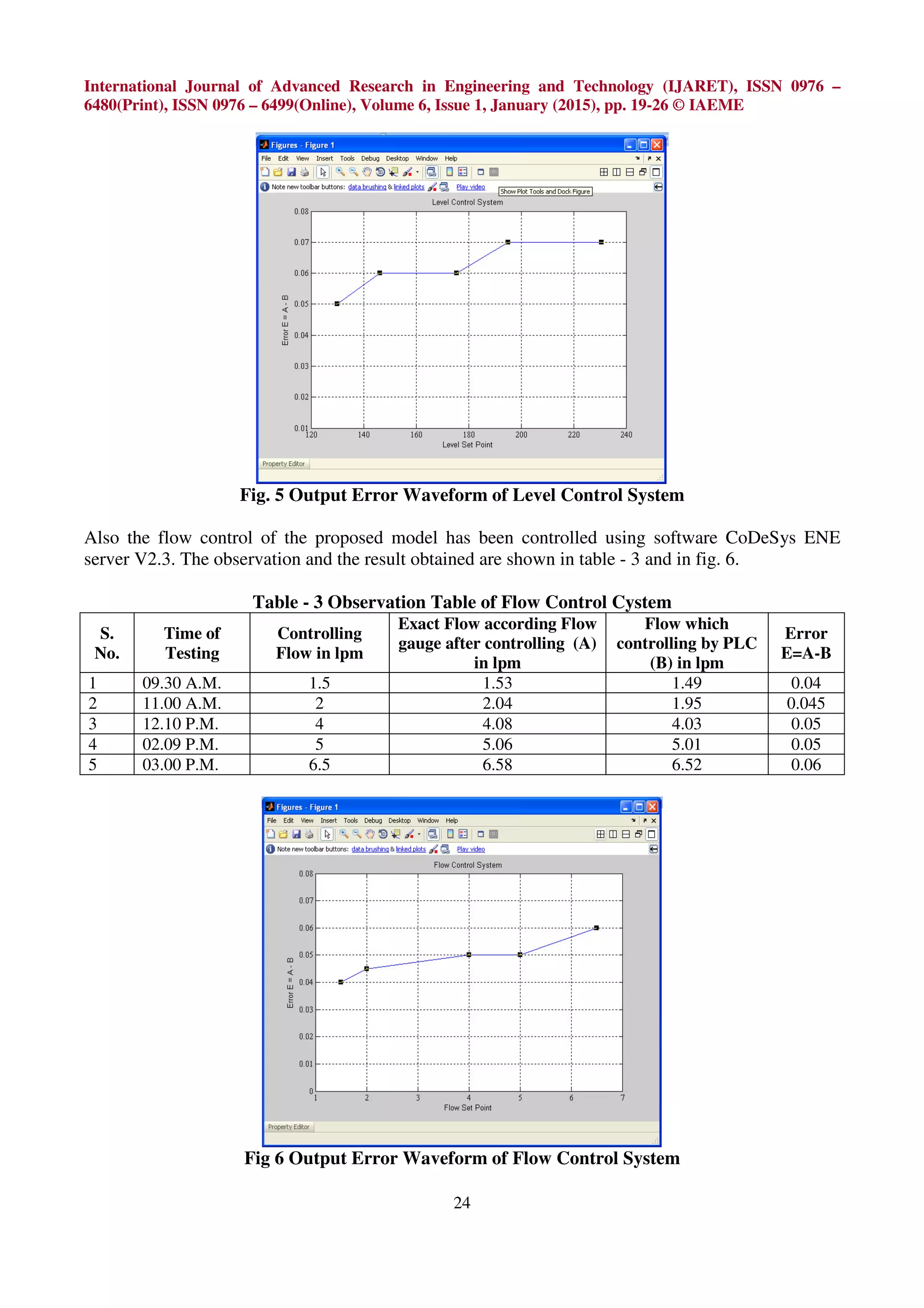

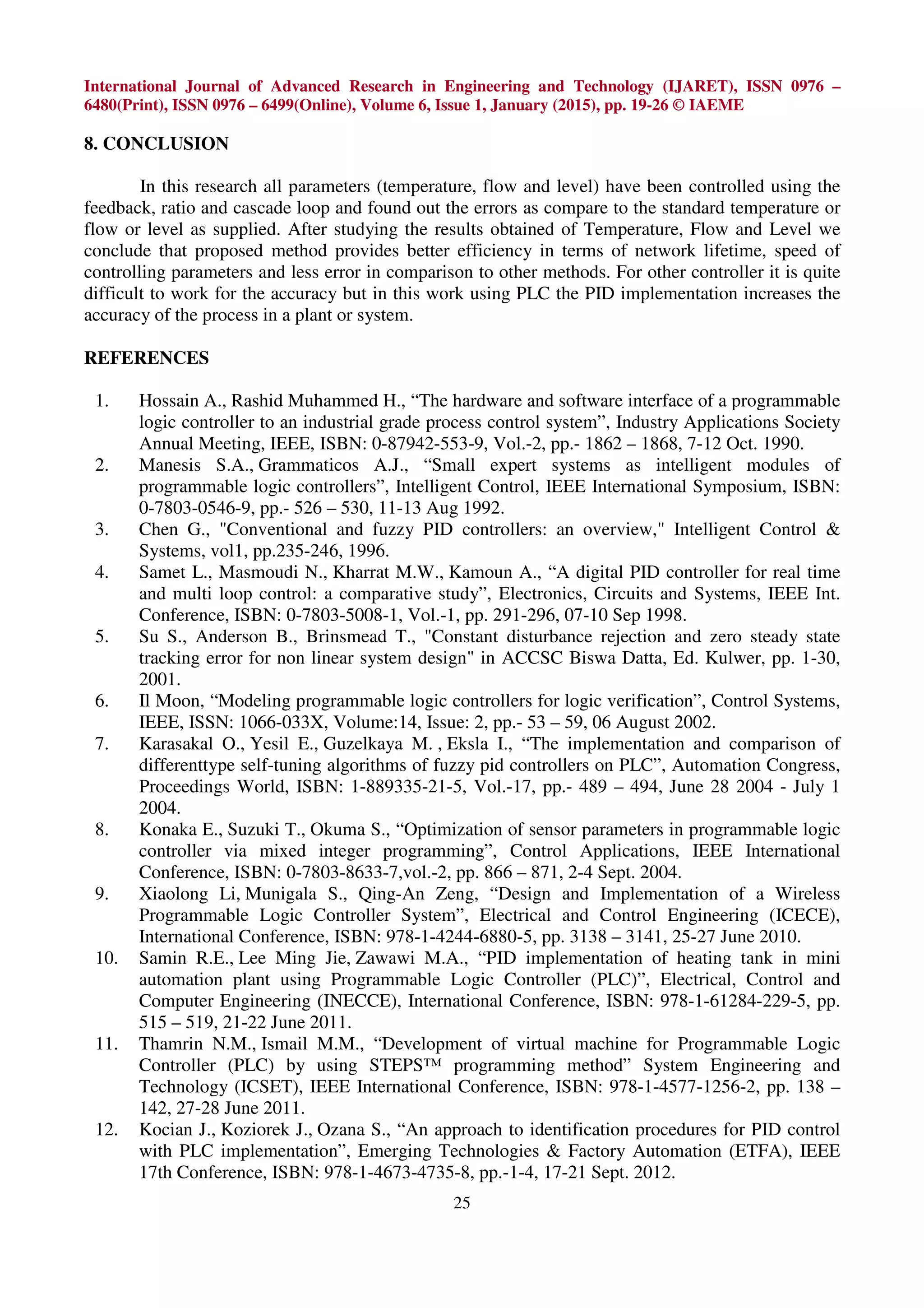

This document describes a PID temperature, flow, and level control system implemented using a PLC. RTDs are used to measure temperature and send signals to the PLC. The PLC controls the process using ladder logic programming. It can implement PID control, feedback loops, cascade loops, and ratio control to efficiently control the temperature, flow and level of a solution to desired setpoints without compromising stability. The system provides control without needing external devices like HMIs or meters by performing all monitoring and control within the PLC program.