This project demonstrates how to interface an A4988 Stepper Motor Driver Module with an Arduino UNO to precisely control a bipolar stepper motor such as the NEMA 17. The A4988 allows microstepping, adjustable current control, and supports supply voltages up to 35V with a maximum output of 2A per coil. Whether for a 3D printer, CNC machine, or robotics project, this tutorial covers pinouts, wiring connections, programming, and troubleshooting.

- Control bipolar stepper motors with precision

- Adjustable microstepping: Full, 1/2, 1/4, 1/8, and 1/16 steps

- Current limiting via onboard potentiometer

- Operates from 8V to 35V motor supply voltage

- Overcurrent and thermal protection built-in

- Compatible with both 3.3V and 5V logic

- Simple two-pin control: STEP and DIR

| Component | Description |

|---|---|

| Arduino UNO | Main microcontroller |

| A4988 Stepper Motor Driver | Motor driver module |

| Bipolar Stepper Motor | e.g., NEMA 17 |

| External Power Supply | 8–35V DC (e.g., 12V) for motor |

| 100µF Capacitor | Between VMOT and GND to prevent voltage spikes |

| Breadboard & Jumper Wires | For prototyping and connections |

| Heatsink (optional) | For cooling the A4988 under high current loads |

-

Power Delivery:

- VMOT pin supplies motor voltage (8–35V)

- VDD pin powers A4988 logic (3.3–5.5V) from Arduino

-

Control Signals:

- STEP pin receives pulses to move the motor

- DIR pin controls rotation direction

- MS1–MS3 pins set microstepping resolution

-

Motor Driving:

The A4988 energizes coils in a precise sequence based on received pulses, enabling accurate position control. -

Current Limiting:

Adjust the potentiometer to prevent overheating and match motor specifications.

-

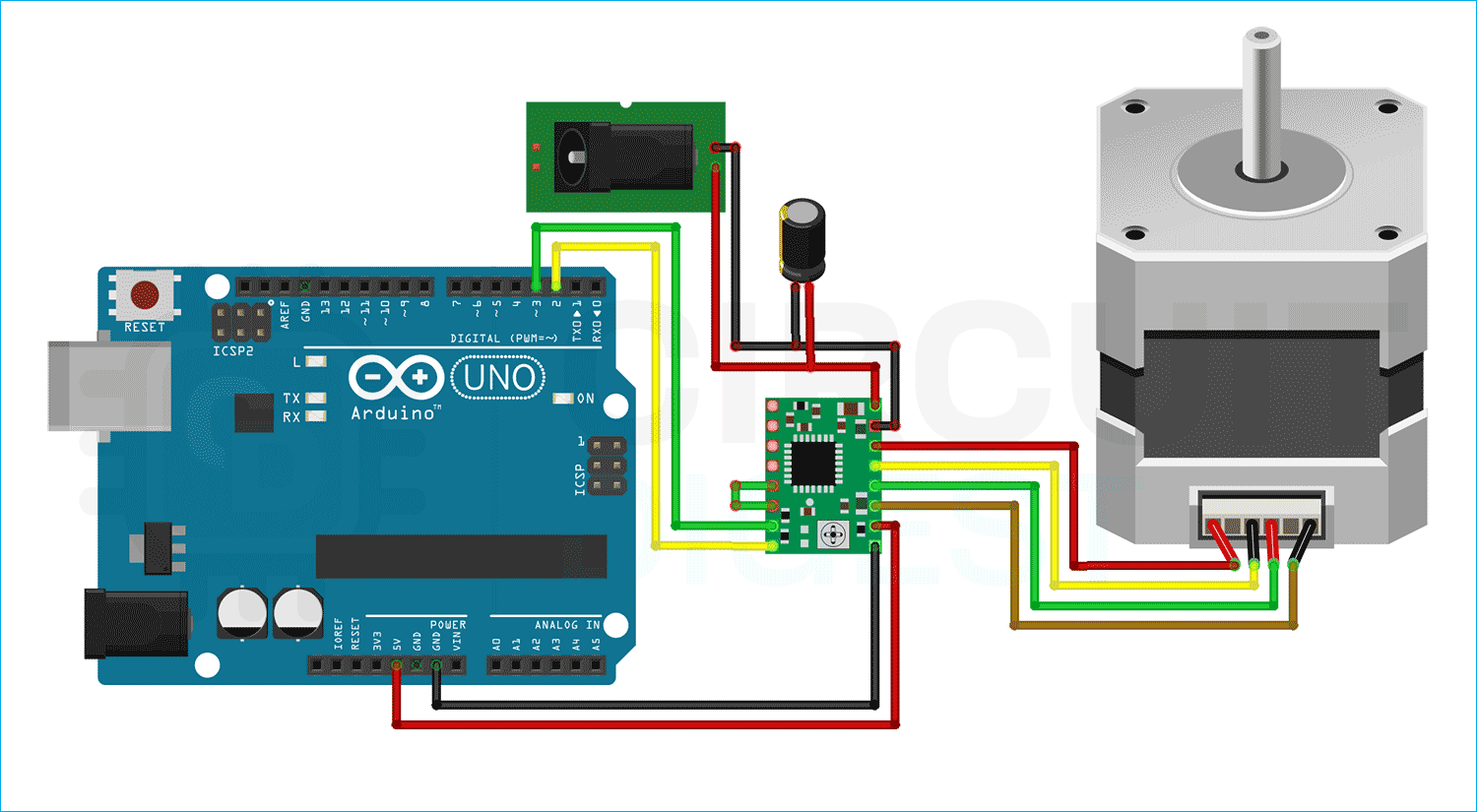

Power:

- VDD → 5V on Arduino

- GND → Arduino GND

- VMOT → External motor supply (e.g., 12V)

- 100µF capacitor between VMOT and GND

-

Control Pins:

- STEP → Arduino D3

- DIR → Arduino D2

-

Motor Output:

- Connect motor coils to 1A, 1B, 2A, 2B according to datasheet

| MS1 | MS2 | MS3 | Microstep Resolution |

|---|---|---|---|

| Low | Low | Low | Full Step |

| High | Low | Low | Half Step |

| Low | High | Low | Quarter Step |

| High | High | Low | Eighth Step |

| High | High | High | Sixteenth Step |

const int dirPin = 2; const int stepPin = 3; const int stepsPerRevolution = 200; void setup() { pinMode(stepPin, OUTPUT); pinMode(dirPin, OUTPUT); } void loop() { // Clockwise rotation digitalWrite(dirPin, HIGH); for (int x = 0; x < stepsPerRevolution; x++) { digitalWrite(stepPin, HIGH); delayMicroseconds(1000); digitalWrite(stepPin, LOW); delayMicroseconds(1000); } delay(1000); // Counterclockwise rotation digitalWrite(dirPin, LOW); for (int x = 0; x < stepsPerRevolution; x++) { digitalWrite(stepPin, HIGH); delayMicroseconds(500); digitalWrite(stepPin, LOW); delayMicroseconds(500); } delay(1000); } | Issue | Cause / Solution |

|---|---|

| Motor not moving | Check wiring, ensure correct coil pairing, verify STEP and DIR signals |

| Overheating | Lower current limit via potentiometer, add heatsink |

| Erratic movement | Secure connections, check for noise interference |

| Driver shutting down | Ensure cooling, verify power supply current capacity |

- 3D Printers

- CNC Machines

- Camera Sliders

- Robotics

- Automated Positioning Systems

| Parameter | Specification | Notes |

|---|---|---|

| Motor Supply Voltage | 8V to 35V | Higher voltage improves torque & speed |

| Logic Voltage | 3.3V to 5.5V | Compatible with Arduino |

| Max Current per Coil | 2A | Requires adequate heat dissipation |

| Microstepping | Full, 1/2, 1/4, 1/8, 1/16 | Set via MS1–MS3 pins |

| Step Frequency | Up to 200kHz | Depends on supply voltage and load |

| Protection | Overcurrent, Thermal shutdown | Automatic fault handling |

| Sleep Current | <1mA | Ultra-low power mode |

If you found this helpful, please ⭐ star this repository and share it with others!

Built with 💡 by Circuit Digest

Making Electronics Simple

Arduino A4988 stepper motor microstepping driver NEMA 17 control

STEP DIR interface CNC positioning 3D printer motor control

Embedded C Arduino project A4988 pinout wiring motor driver tutorial