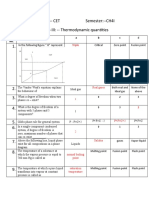

CP/13/….

,00,1220

PROCESS CONTROL PLAN

CORE TEAM:- MR. KULDEEP, MR. INDERJEET SINGH, CUSTOMER ENGG. APPROVAL DATE

CUSTOMER :- INTERFACE MICROSYSTEMS

PROTOTYPE PRE-LAUNCH PRODUCTION MR. DHIRENDRA TIWARI, MR.VIVEK SAHA (IF REQUIERD):-

PART NAME :-TERMINAL SUPPORT-785 CUSTOMER QUALITY. APPROVAL DATE

KEY CONTACT / PHONE NO:- MR. KULDEEP, 9818078232 IMPL.DATE:- 04.12.2020 REVIEW DATE:-

PART NUMBER :- 24-R1-785-1-0 (IF REQUIERD):-

PROCESS PROCESS M/C ,MOULD CHARACTERISTICS PRODUCT PROCESS PRODUCT EVAL./ MEAS. SAMPLE REACTION

RESPONSIBILITY

NO. NAME TOOL FOR MFG. PRODUCT DESCRIPTION PARAMETERS SPECS. METHOD SIZE FREQ. REF. DOC. PLAN

MOULDING GRADE VASW-150-I EACH LOT &

SUPPLIER MTC / REJECT &

RAW BAKELITE THIRD PART BOP INSP &

10 LAB TEST BOP RETURN TO

MATERIAL POWDER MTC ONCE IN 6 TEST REPORT

POWDER COLOUR BLACK REPORT INSPECTOR PARTY

MONTH

VISUAL DISPLAY

*MTC TEMP. 50°c ~ 70°c

ON MTC

*CORE HALF TEMP. 175°c ± 10°c

SOP / EOP INSP

REPORT

*CAVITY HALF TEMP. 185°c ± 10°c EVERY SETUP (ALL

PARAMETERS

ARE RECORDED)

*INJECTION TIME 2 ~ 6 SEC.

HOLD TIME 4 ~ 8 SEC.

PLASTIC DELAY TIME 15 ~ 25 SEC.

IF PARAMETER

IS NOT UNDER

PLASTICIZING SCREW END VISUAL DISPLAY Q.C.

20 MOULDING 90 TON 12 ~ 17 MM CONTROLLED

THERMOSET POSITION. ON MACHINE INSPECTOR

RESET MACHINE

INJ MOLDING

PARAMETER

MACHINE

WITH 8 *CURING TIME 35 ± 10 SEC.

CAVITY MOLD

*INJECTION PRESSURE

100 ± 10 PQCS

(Kgf/Cm2)

(ONLY STAR

EVERY 3 HRS.

MARKED ARE

HOLD PRESSURE (Kgf/Cm2) 85 ± 10 RECORDED)

LOCKING PRESSURE

90 ~ 100

(Kgf/Cm2)

*CYCLE TIME 60 ± 10 SEC.

NO. OF CAVITY. 1 ~ 8 CAVITY VISUAL

PAGE 01 OF 02

PROCESS PROCESS M/C ,MOULD CHARACTERISTICS PRODUCT PROCESS PRODUCT EVAL./ MEAS. SAMPLE REACTION

RESPONSIBILITY

NO. NAME TOOL FOR MFG. PRODUCT DESCRIPTION PARAMETERS SPECS. METHOD SIZE FREQ. REF. DOC. PLAN

DIAMETER Φ 12.8 + 0.2 /- 0.10 DVC

DIMENSION 7.9 ± 0.10 DVC

DIMENSION 16.2 ± 0.2 DVC

SOP / EOP INSP

EVERY SETUP

REPORT

DIMENSION 5.9 ± 0.10 DVC

DIMENSION 6.4 + 0.10 /- 0.05 DVC

IF SPECS ARE OUT

ONE SHOT INSP. OF TOLERANCE

DIMENSION 9.1 ± 0.20 DVC / VMS QC. INSPECTOR VALUE VERIFY PROD.

REPORT MADE

LOT & MOULD REPAIR

MEASURING

30 INSPECTION DIMENSION 2.0 ± 0.05 DVC

INSTRUMENTS.

DIMENSION 6.35 ± 0.10 DVC / VMS

ANGLE 2 X 130° ± 2° VMS 1 TIMES / SHIFT PQCS

DIMENSION 2 X 7.6 + 0.20 VMS

DIMENSION 2 X 6.6 + 0.20 VMS

NO FLASHES, NO

EVERY TIME &

DENT, NO CRACK , NO QC.INSPECTOR / REJECT MATERIAL

APPEARANCE VISUAL EVERY SHOT RECORDING PQCS

SWELLING, NO SHORT OPERATOR SCRAP

EVERY HOUR

MOULDING

IF FLASH NOT

NO FLASHES, NO

PROPERLY

DENT, NO CRACK , NO AS PER PATROLING INSP. OPERATOR/

40 DEFLASHING KNIFE/MANUAL APPEARANCE

SWELLING, NO SHORT

VISUAL

SAMPLING PLAN

3 TIMES / SHIFT

SHEET QC.INSPECTOR

DEFLASHED

REWORK THE

MOULDING

MATERIAL

AS PER PATROLING INSP.

NO FLASHES, NO 3 TIMES / SHIFT QC.INSPECTOR.

SAMPLING PLAN SHEET

FINAL DENT, NO CRACK , NO

50 INSPECTION

MANUAL APPEARANCE

SWELLING, NO SHORT

VISUAL / GAUGE REWORK / SCRAP

MOULDING EVERY PCS EVERY TIME .--- FINAL INSPECTOR

DIMENSIONS IF LOT IS NOT AS

PER STANDARD

60 PDIR AS PER CUSTOMER INSPECTION STANDARD PER LOT PDIR QC INSPECTOR.

VRIFY THE

APPEARANCE COMPLETE LOT.

HEAT SEALING

PHYSICAL PDIR REPORT/

PACKING & M/C & POLYTHENE FG STORE RECOUNT &

70 DISPATCH WEIGHING BAGS

AS PER STANDARD COUNTING / 400 / PKT EVERY LOT IDENTIFICATION

KEEPER RECTIFY THE LOT

WEIGHING SCALE TAG

SCALE

CHANGE DETAIL:-

REV NO. REVISION DETAIL DATE SIGN

DOC NO. F-NPD-13 REV NO.02 DATE 01.04.2018

PAGE 02 OF 02

PREPARED BY APPROVED BY